Yes, but then many more posts and hammering. What are good posts and fasteners for that?Run it up the side edges of the panels.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Vertical Bi-Facial Solar Panels, Solar Fencing (not portray)

- Thread starter eXodus

- Start date

littleharbor2

Solar Addict

I don't know your foundation plan. You wanted to know how not to shade your panels. Mount the uni strut to the panels then bolt it to the ballast/foundation/whatever. I'd just set them in concrete myself

eXodus

Solar Addict

- Joined

- Jul 27, 2020

- Messages

- 1,482

I am just thinking Square Galvanized Fence posts. Better would be aluminum - but also much more expensive.Uni-strut would be cheap and easy, but then I guess it create a little shading on the backside.

Depending on your soil - can just use a manual fence post driver or rent a hydraulic driver - or contract a fence company.

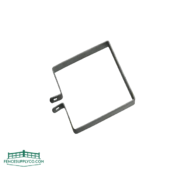

We could use those kind of fence clamps:

to mount the panels. Could use 4, 6 or 8 depending what the panel manufacturer backside specification needs.

Tension Band Square Galvanized

Tension Band Square - Galvanized DESCRIPTION: Square Tensions bands are a critical part of every permanent chain link fence installation using square fence posts, as they connect the fence mesh to the terminal end posts of the fence, by use of a tension bar. The Shape of each tension band is...

fencesupplyco.com

fencesupplyco.com

The installation would not need any drilling - just a bolt and nut through the fence band and the rear of the panel. The slotted hole on the band would allow for some imperfection while installing the posts.

teal95

Solar Enthusiast

Not much "give" in that if you don't have your posts perfectly placed.

eXodus

Solar Addict

- Joined

- Jul 27, 2020

- Messages

- 1,482

It really isn't hard to do fences like this, I have installed 'colourbond panel' fences (as in the aluminium panels, not solar panels' lol) which are quite similar at the old place- quite similar in wind loadings to solar panels, and the same method and likely the same or similar could be done for mounting solar panels instead of colourbond sheets- precut lengths of 'u channel' of the right size to hold the frame of the panel- attach to posts concreted into the ground, fit panels and bingo- instant solar panel fence... (not mine lol, but almost identical- even to the 'step down' which took it from the 'privacy screen height' of the back yard down to the lower fence in the front yard...true, the placements would need to really close.

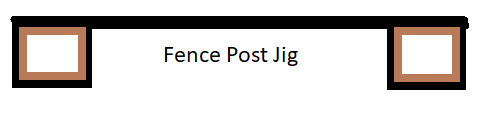

Would need to build some sort of Jig to make them go in the ground at the right spot.

View attachment 195294

I did the back yard fences on the sides and back of the old place, and it literally took less than a day to do an entire boundary fence with nothing more than basic tools and a hand 'post hole digger' auger

Bunnings Hardware in here in Australia has a whole bunch of 'how to' videos online, this is the exact same fence panels I used (first bit is only 14 seconds long and shows the basic idea of how its done- pt 2 and 3 are about 5 minutes long and don't need to be watched- they literally are the complete 'how to' sections...)

bunnings diy-how-to-build-a-colorbond-fence

These are a simple fence to make, and even if you had to 'make your own' top and bottom channel rails for the panels etc- it really would be simple to do- anyone incapable of this shouldn't be playing around with any form of fencing in the first place... let alone solar

ImAnIdiotPleaseBePatient

Solar Enthusiast

- Joined

- Dec 10, 2022

- Messages

- 425

Does solar have setback requirements from property lines in certain areas? I wonder how that would work if you were trying to incorporate solar panels into a fence.

teal95

Solar Enthusiast

I'm wondering about setbacks also as when I did my ground mount it had to be 25' from the property line.

OffGridForGood

Catch, make or grow everything you can.

apply for permit for "panelized" fence, then use PV panels lol unless the next yard has teenagers, and slingshots...I'm wondering about setbacks also as when I did my ground mount it had to be 25' from the property line.

Depends- here where I am in Australia, if it is a ground mounted solar array (ie conventional ground racking frame) then here there is a 3m minimum setback from the fenceline (that applies to all structures here- a shed, garage, carport etc all have to have a 3m setback unless an exemption is applied for and granted)- however 'fences' of no more than 2m height are exempt and can be on the property boundary- there is nothing saying in the regs here WHAT you make the fence out of- so as long as your neighbour agrees, you could put up bifacial solar panels (the other option is one done here when neighbours have different ideas on what they want for a fenceline, is both pay for the rails and posts, and each then can have a 'different side' paneling attached on 'their side' of the rails, at their own cost...Does solar have setback requirements from property lines in certain areas? I wonder how that would work if you were trying to incorporate solar panels into a fence.

(this is actually quite common where one side may want a traditional 'wooden paling' fence, and the other wants say colourbond panels or bricks instead- you can both have what yo want on 'your side' but the posts/rails costs are split 50/50)

If that was the case, then you could use a 'normal' single sided panel on that fence- you'd only get a half days production instead, but single sided panels are cheaper than bifacials... and some is better than none...

Last edited:

OffGridForGood

Catch, make or grow everything you can.

better yet, introduce your neighbours to solar, and put PV panels for the fence, every second panel facing to your yard/their yard alternating, half yours and half theirs connecting to their own solar power system. share the cost for the uprights and framing.

eXodus

Solar Addict

- Joined

- Jul 27, 2020

- Messages

- 1,482

In most agricultural settings it's easy. In residential - no way of knowing. Every city, subdivision, even neighborhood can make it's own rules.I wonder how that would work if you were trying to incorporate solar panels into a fence.

Many parts of Europe are working on something like a "right to solar" In Germany even renters in apartments are allowed by law to have 800W on the balconies - the owner of the building can not do much about it. Would need similar laws to enable solar fencing everywhere.

I like the idea of a cost/profit sharing model for neighbors. That could be a interesting business plan.WHAT you make the fence out of- so as long as your neighbour agrees, you could put up bifacial solar panels (the other option is one done here when neighbours have different ideas on what they want for a fenceline, is both pay for the rails and posts, and each then can have a 'different side' paneling attached on 'their side' of the rails, at their own cost...

(this is actually quite common where one side may want a traditional 'wooden paling' fence, and the other wants say colourbond panels or bricks instead- you can both have what yo want on 'your side' but the posts/rails costs are split 50/50)

Both get additional solar yields, from a marginal space which was just a fenceline before. With panels getting cheaper - the cost difference between a privacy fence and a solar fence should be minimal in a few years.

eXodus

Solar Addict

- Joined

- Jul 27, 2020

- Messages

- 1,482

eXodus

Solar Addict

- Joined

- Jul 27, 2020

- Messages

- 1,482

bunnings diy-how-to-build-a-colorbond-fence

These are a simple fence to make, and even if you had to 'make your own' top and bottom channel rails for the panels etc- it really would be simple to do- anyone incapable of this shouldn't be playing around with any form of fencing in the first place... let alone solar

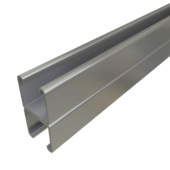

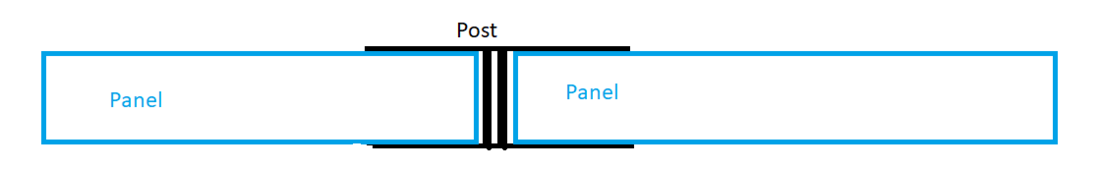

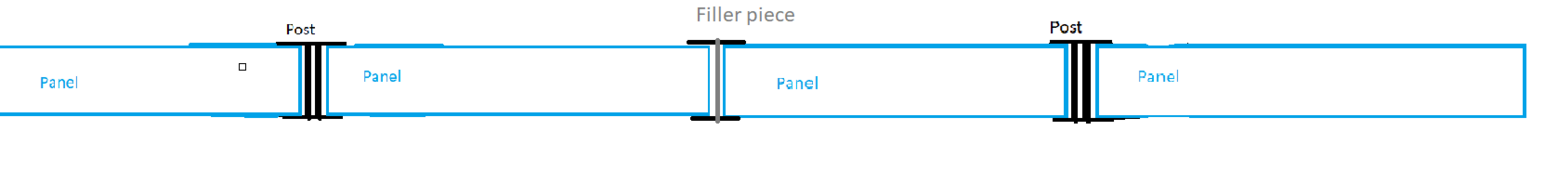

Just watched the installation videos - I those back to back U-shaped rails are the key to the system

So the panels would just sit in between the Pole rails - the top bar keeps the post aligned and from pushing apart. Another very nice benefit of this design - since the panels are not fixed mounted - they can freely expand and contract with heat. Should extend lifespan.

Not sure if would use this in a high wind area out in a field - but definitely could be a interesting system for residential neighborhood.

Lets go for it

shadowmaker

Solar Addict

To maximize bifacial output there should be decent ground clearance (0,8m or more) and optimally some spacing between panel and post to get more backside irradiation. But of course it can be used as "normal" fence and just lose little production.

At least in here they will make any extruded aluminum profile you want, but you'll need to order more than 500m. I think it was about 8e/kg when I asked last year.

At least in here they will make any extruded aluminum profile you want, but you'll need to order more than 500m. I think it was about 8e/kg when I asked last year.

You would be surprised how much wind those colourbond panel fences can handle- the back fence (at the time) was exposed to a cow paddock, so basically there was nothing for about 25km in that direction except fields to stop the wind- and it held up to some nasty weather- including a storm that demolished the local church (took the roof and and demolished one wall) and tipped two 'de-mountable' school classrooms off their foundations- they took a beating that day and were fine the next day...Just watched the installation videos - I those back to back U-shaped rails are the key to the system

View attachment 195423

View attachment 195426

So the panels would just sit in between the Pole rails - the top bar keeps the post aligned and from pushing apart. Another very nice benefit of this design - since the panels are not fixed mounted - they can freely expand and contract with heat. Should extend lifespan.

Not sure if would use this in a high wind area out in a field - but definitely could be a interesting system for residential neighborhood.

Lets go for itI get dibs on the Design Patent. (eXodus Industries TM) You can take up distribution and installs in Australia.

Plus as shadowmaker mentioned it would allow the panels to be raised above the ground further for better production (plus the bottom rail could be 'thickened' in the process, adding stiffness to the length between the posts as well as increasing the panel height. It also decreases the distance between posts (rather than two posts per panel, it would be two posts every two or three panels...

I would be surprised if an existing extrusion couldn't be found already but they are a very simple design for it- the H simply has to be 'big enough' between the legs to fit the panels existing frame in (the existing channel is already very close to the thickness of many slim panels, because it has to accommodate the thickness of the colourbond and it's 'hills and valleys'

The door on my shed uses this design as well (in gal steel of course, rather than aluminium) but shows the way it 'holds' the colourbond steelthe shed is made of- it would do the same with a panel frame... thats the inside of it on the right

This is a bit of the scrap stuff still at the back of the shed to show the profile they used that 'gap' at the top right on mine is almost exactly an inch (35mm)

That frame runs right around the door on the shed- which is 5m wide and 4m high, swung from one end on three hinges on the right in that picture (standard 'farm gate' hinges)

It had a slight 'droop' in that shot- since corrected by an adjustable steel cable and tensioner added as a 'diagonal brace' from top right to bottom left

eXodus

Solar Addict

- Joined

- Jul 27, 2020

- Messages

- 1,482

I like the lower rail two/three panels between two post idea - it should make install pretty simple - just drop the panel in - slide it to the side, it will stay upright through the H-rail on the side.Plus as shadowmaker mentioned it would allow the panels to be raised above the ground further for better production (plus the bottom rail could be 'thickened' in the process, adding stiffness to the length between the posts as well as increasing the panel height. It also decreases the distance between posts (rather than two posts per panel, it would be two posts every two or three panels...

Could put a filler piece the middle of those panels - that would give the fence a more uniform appearance.

eXodus

Solar Addict

- Joined

- Jul 27, 2020

- Messages

- 1,482

500m is not much when you need 5m per panel. (plus whatever high you elevate off the ground x2) 100m of fence line. 100 postsAt least in here they will make any extruded aluminum profile you want, but you'll need to order more than 500m.

For fence guys with a hydraulic ram they get this done before their second breakfast.

Similar threads

- Replies

- 2

- Views

- 278

- Replies

- 41

- Views

- 2K

- Replies

- 6

- Views

- 763