AWG 8 is quite small.

I'm used to work in metric, NOT in imperial.

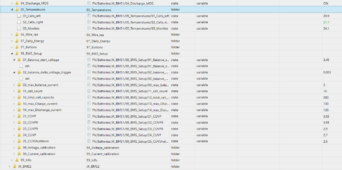

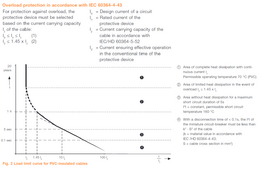

For this kind of sizing, I usually refer to the great Legrand Power Book 04 - Sizing conductors and selecting protection devices (it's quite old from 2009):

Cable current capacity depends on:

- Type of Insulation (PVC: 70°C, XLPE: typically 90°C, Silicone: see Manufacturer Information, EPR: Depends - some are 60°C [H07RN-F] -

some are 70°C - some are 80°C [NSGAFOU Cable in Germany for Instance])

- Installation Method (under thermal insulation: A, in conduit on a wooden wall: B, on a wooden wall: C, D: in the ground, E/F: in free air). If you want to be conservative you can choose B1/B2. If you want to be more realistic then C might be a good option.

- How many cables / wires you have in parallel (group of circuits)

- Ambient temperature

Assuming pretty much standard ambient temperature and only PVC2 / PR2 (you don't have 4 wires in parallel all fully loaded etc) you are somewhere in this region depending if PVC or XLPE 90°C:

View attachment 202606

With this in mind, for a *Breaker* I'd select 40A Rating.

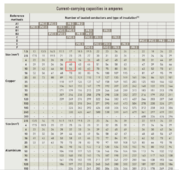

However, for a fuse, please refer to the great ABB guideline

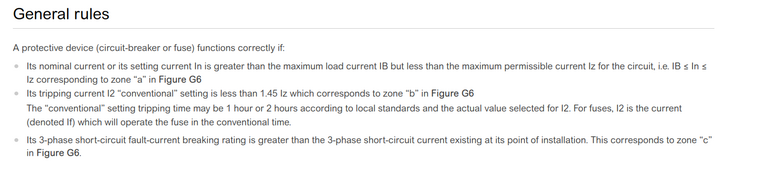

Also from Schneider Electrical Installation Wiki:

View attachment 202608

View attachment 202609

View attachment 202610

View attachment 202611

Applying Condition (1):

(1) Ib (your circuit current) <= In (rating of breaker or fuse) <= Iz (carrying capacity of the cable ~ 40-46 A from the table above)

Note that

By virtue of its high level of precision the current I2 is always less than 1.45 In (or 1.45 Ir) so that the condition I2 ≤ 1.45 Iz (as noted in the “general rules” above) will always be respected.

Now, for a fuse you need to check that condition as well !

(2) Fuse Current vs Tripping Time Characteristic must satisfy

I2 <= 1.45 x Iz = 1.45 x 40A = 58 A

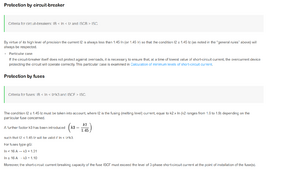

I take for instance a gR type fuse

REF 492033 / 492034 / 492035 / 492036 / 492037 / 492038 / 492039 / 492040 / 492133 / 492134 / 492135 / 492136 / 492137 / 492138 / 492139 / 492140 / PMX 22x58 / BAC 22x58

www.dfelectric.es

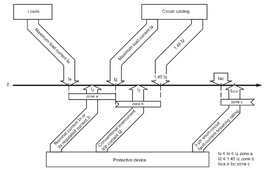

Now - PLEASE CORRECT ME IF I'M WRONG HERE - The I2 Current corresponds to 1h duration (according to ABB document)

View attachment 202613

So a 40A gR fuse is on the edge for the second condition but still satisfies it [50A < 58A] (but you can argue that the cable Iz is probably higher than 40A that I very conservatively stated).

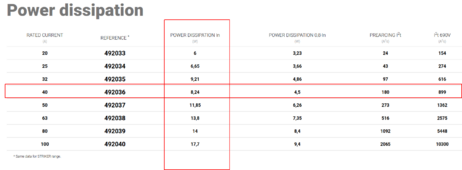

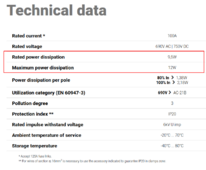

Last but not least check the power dissipation vs your fuse holder / base

View attachment 202614

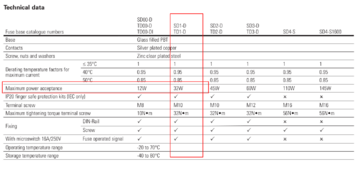

Example of fuse holder:

REF 485301 / 485302 / 485303 / 485304 / 485305 / 485306 / 485307 / 485308 / 485309 / 485310 / 485311 / 485312 / 485313 / 485314 / 485315 / 485316 / 485320 / 485321 / 485322 / 485323 / 485324 / 485325 / 485326 / 485327 / 485328 / 485329 / 485330 / 485331 / 22x58 gG / 22x58 aM / 22x58 aR / 22x58...

www.dfelectric.es

View attachment 202615

Note that a gR fuse is NOT very fast. If we talk about fuse speed (from FASTEST to SLOWEST): aR < gS < gR < gG

So it mostly depends what TYPE of fuse you select.

Then you will have a range of SIZE (NH0, NH1, NH2 blade fuses, 10x38 mm, 22x58 mm, ...) fuses.

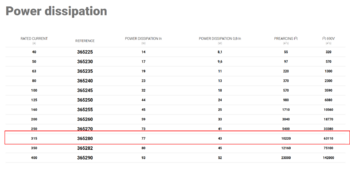

My protection scheme is based on:

- JK BMS (200A)

- 315A aR Fuse (

https://www.tme.eu/dk/en/details/365280/nh-fuses/df-electric/) in NH1 Fuse Base (

https://www.omnical.co/products/eaton/sd1-d/2262274 +

https://www.omnical.co/products/eaton/sd12-sk/2262273)

- 100 A Characteristic B Circuit Breaker (Schneider C120H)

And for the Specifics in my case:

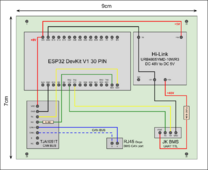

View attachment 202617

View attachment 202618

Now Power dissipation scaling of Pn x (Ioperation / Irated)^2 does NOT really work that well with fuses. The reason is simply that the resistance variation versus temperature is significant. Already if you just consider an Aluminium or Copper conductor, at 300°C you have DOUBLE the resistance / losses than at 20°C ! Fuses might be even more.

Nevertheless, you are being conservative with Pn x (Ioperation / Irated)^2 - If you try Pn x 0.8^2 = 49W while the table states 43W ...

So for me very conservatively:

P100 = 77 W x (100A / 315A)^2 = 7.76W

But of course it's also OVERSIZED on PURPOSE for other reasons (e.g. Power/Thermal Cycling, avoid tripping on Inrush, etc).

EDIT 1: and of course if you are based in US / using UL-CSA components, you probably should refer to a UL standard, which I'm NOT very familiar with

EDIT 2: if you select an aR fuse, you will have NO OVERLOAD PROTECTION AT ALL (only short-circuit protection). And if you *try* to overload an aR fuse, it will behave like a bomb and explode/disintegrate in a non-normal way (I have seen pictures of this type of fuses with a bullet-like hole in it as well ...)

EDIT 3: of course you need to make sure that your fuse is suitable for DC usage (most are AC !)