robbob2112

Doing more research, mosty harmless

I was asking about the OP, and wondering if he has anything on his connections.

I would highly recommend going back through and redoing all the connections with no-ox-id special. Just a thin coating on any mating electrical connections. It should prevent any of them from oxidizing and becoming a bad/hot connection in future so long as the are occasionally check and retorqued.I did not. It's been installed in a different location for nearly three years now. But I never checked it's temp much before and don't remember what the findings were.

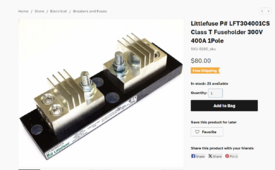

Blue Sea Systems bought direct from Blue Sea Systems.Did we ever get the holder model info here?Could be a cheap knockoff holder.

johnsonssurplus.com

johnsonssurplus.com

Surely a tight connection won't be able to oxidise on the mated surfaces anyway?I would highly recommend going back through and redoing all the connections with no-ox-id special. Just a thin coating on any mating electrical connections. It should prevent any of them from oxidizing and becoming a bad/hot connection in future so long as the are occasionally check and retorqued.

106F or 41C sounds normal. Fuses have to use thin metal conductor so it can melt in event of over current. That thin conductor will have higher resistance than your cables and will run hot.Was drawing 318A ...for ten minutes. ...type T 400A fuse was at 106 deg F. Felt warm to the touch.

I’ve had a new Class T fuse come slightly warped out of the box.Ok, got out to the camper today. Replaced the type T fuse with a brand new Buss from Blue Sea Systems. No sign of corrosion when I removed the old one. Cleaned the fuse and fuse holder anyway with deoxit then emory paper. Installed new fuse and ran another load test.

Original test: 71 deg F ambient. 325A load for 10 minutes. Type T fuse got to 106 deg F (35 deg F above ambient)

Today's test: 63 deg F ambient. 308A load for 10 minutes. Type T fuse got to 84 deg F (21 deg above ambient)

So, maybe it's better. Happy that I replaced it because the original fuse took some abuse early in its life from a loose connection.

Surely a tight connection won't be able to oxidise on the mated surfaces anyway?