MicrohydroBIGI

New Member

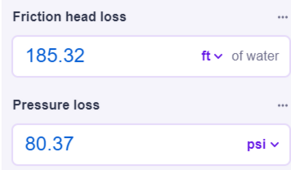

Hey guys i have been working on a hydro project here on the big island of hawaii for a fee months now have layed 1100ft of 2inch line with around 65ft of drop or so. I have gone through a handful of cheap chinese turbines so far and am on my third one as of now. The link to the turbine can be seen below.

MHJYD 300W 1000W 220V... https://www.amazon.com/dp/B09WYP8QWF?ref=ppx_pop_mob_ap_share

I have had issues with each turbine in power production. I assume based on my head and flow rate i should be producing anywhere from 0.3-0.6kw of electricity. Is this incorrect? When i test using a volt meter on the DC side of the rectifer im getting 273v and 0.61amps. Not much power correct? That was measured when hooking the dc leads of the rectifer to a 24v battery bank for just a moment. What charge controllers work with an input of 276v? How do i put a load on the turbine to see what my max power is with a voltage that high? Is it safe to charge 24v bank with that high of voltage or any long length of time, surely not?

MHJYD 300W 1000W 220V... https://www.amazon.com/dp/B09WYP8QWF?ref=ppx_pop_mob_ap_share

I have had issues with each turbine in power production. I assume based on my head and flow rate i should be producing anywhere from 0.3-0.6kw of electricity. Is this incorrect? When i test using a volt meter on the DC side of the rectifer im getting 273v and 0.61amps. Not much power correct? That was measured when hooking the dc leads of the rectifer to a 24v battery bank for just a moment. What charge controllers work with an input of 276v? How do i put a load on the turbine to see what my max power is with a voltage that high? Is it safe to charge 24v bank with that high of voltage or any long length of time, surely not?