300A ... didn't realize it was so much, but I'm finding references to about 25A per plug, 200A for eight.

Finally got around to getting a Digital Current/Voltage meter. With the shunt on top, it's good for up to 200 Amps and 200 Volts AC/DC. With that meter I can finish doing my GP testing with the GP controller and 8 GP's I made a year or so ago. Stay tuned for futher updates, if I can make a video...

www.oilburners.net

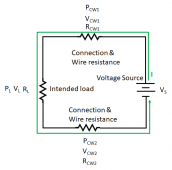

The purpose of this test is to check the glow plug voltage and current to ensure correct operation.

www.picoauto.com

www.thedieselstop.com

I have GMC K2500 with 6.5 turbodiesel.

I should check it next time with clamp ammeter.

"draws 300a alone"

You use glow plugs alone, then after they shut off use starter alone, correct? So never both at once?

I would have thought 4x 280 Ah could deliver several "C" for seconds or minutes, or for a big engine 2p4s with 560 Ah.

I'm still thinking of putting battery & inverter in my truck. Might do a cheaper 12V system (rather than 48V). I would want to have self jump-start capability. K2500 is supposed to have 2x 800 CCA batteries in parallel. I've used 700 Ah Optimas, now Oddessy. My hope is 280 Ah LiFePO4 could start it if needed. Would think even if that is abusive, would be OK for occasional use (unlike your replacement plan.)

Obviously you would connect starter bypassing BMS. BMS could disable solenoid at low battery.

But you need to prevent high voltage disconnect which would blow alternator diodes. What you might do instead is shut off regulator (easier said than done for internal regulator.)