KITROBASKIN

Solar Enthusiast

Inherited this system though did replace batteries January ‘21. The existence of diysolarforum was unknown at the time. LFP batteries were too expensive an upfront cost for us at the time. (Not so now!)

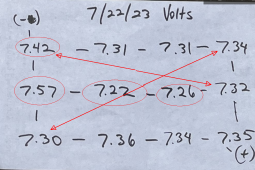

I did tighten the battery terminal connections this early spring, some got a little tiny bit tighter. Did not use a torque wrench. First (not dated) readings were before that in mid February.

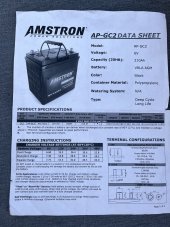

Interstate battery vendor gave me (I had to ask for it) this spec sheet; said it was the same battery, different label.

About 15 year old charge controller receiving 15 year old Conergy 175WX4 panels and 8 ancient Arcosolar/Carrizo panels maybe outputting similar to one of the Conergy panels. Operating voltage from array is labeled 68v, maximum 90V. Current 17A, 22A

Readings taken at different stages of absorption I think.

Is there anything I can do to extend their life? Was thinking some batteries were getting worked harder due to their location and maybe rotating them would help but this is not based on knowledge.

We now have two other LFP systems: one covers Viasat internet and summer ventilation, other is mobile providing supplemental and emergency. The lead AGM rarely go below 85% charged and with our sunny location, float maybe 94% of the days.

Thank you for taking the time to look at this and any help you can offer.

Kitro

I did tighten the battery terminal connections this early spring, some got a little tiny bit tighter. Did not use a torque wrench. First (not dated) readings were before that in mid February.

Interstate battery vendor gave me (I had to ask for it) this spec sheet; said it was the same battery, different label.

About 15 year old charge controller receiving 15 year old Conergy 175WX4 panels and 8 ancient Arcosolar/Carrizo panels maybe outputting similar to one of the Conergy panels. Operating voltage from array is labeled 68v, maximum 90V. Current 17A, 22A

Readings taken at different stages of absorption I think.

Is there anything I can do to extend their life? Was thinking some batteries were getting worked harder due to their location and maybe rotating them would help but this is not based on knowledge.

We now have two other LFP systems: one covers Viasat internet and summer ventilation, other is mobile providing supplemental and emergency. The lead AGM rarely go below 85% charged and with our sunny location, float maybe 94% of the days.

Thank you for taking the time to look at this and any help you can offer.

Kitro

Last edited: