Individual 2V batteries you could charge separately, rather than "equalizing" by over-charging others in series to bring up the lowest.

A single string of batteries or cells minimizes issues with parallel batteries. But it also means if one string fails you have zero.

You can select larger capacity battery or cell to make it 1 string. At some point the battery would be too heavy to move (like a forklift battery). 1x 12V, 2x 6V, 3x 4V, 6x 2V. Any of those can be made out of 100 lb. to 150 lb. batteries, something you can move with a dolly.

Higher voltage is another way to get more capacity, e.g. 4x 12V in series for 48V.

But your 1200W inverter is a reasonable size for 12V system.

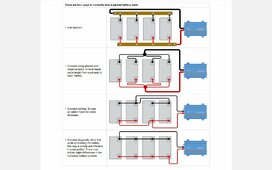

If you connect 2 or 4 batteries in parallel (or 8), there are ways to connect diagonally, then diagonally again, maintaining perfect match. So I would suggest 4 not the 6 batteries you're considering. Better though to have 4x 6V.

You can use wet cell FLA, like Trojan golf cart, or Rolls Surette for premium.

But it is said you will kill your first battery bank. So best to start cheap.

You can use AGM. My bank is 8s 6V 405 Ah SunXtender, for 48V 20 kWh.

AGM is zero maintenance, but must be charged correctly. And sufficiently as mentioned by others; need enough PV. More freeze resistant, essentially freeze-proof fully charged. Quality batteries have about 10 year float life, and 700 cycles.

LiFePO4 is another option. Many advantages, including OK left partially charged. But can't be charged below freezing.

You can get a small all-in-one, 24V or 48V, with MPPT charger.

I'm not sure I see the reason for using components, in a low wattage system with large battery.