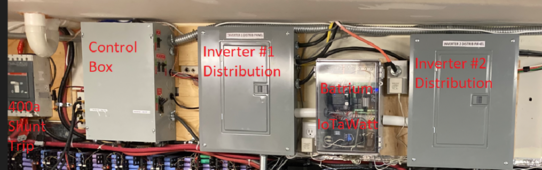

I see no reason to add a redundant BMS when using a Batrium.

The main takeaway from any of this is fuses for batteries should be Class T or similar construction. Originally when I built my truck camper system, the ANL was popular, over time people tested the ANL and found the Class T was superior when the fuse blew. I had built with ANL back then and it was suggested I switch to Class T which I eventually did.

I do not understand the mindset where the Batrium needs to have a BMS on each 48V battery when a Class T is used on each battery. A mosfet BMS can fail under high current and still allow high current to pass. The only safe system is a Class T type fuse that will blow, not sustain an arc, start/sustain ignition and not blow molten material around.

I buy my Class T fuses from Don Rowe for $60 each and that includes the holder. Protection so cheap it doesn't make any sense to do anything else.

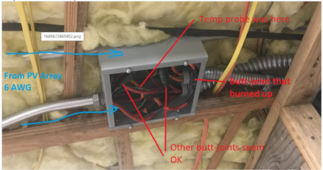

Fuses fail too. Even the best. The damage - fire gets started even after fuses blow sometimes. Think ppl are saying add bms as parallel…to batrium. You are saying class t fuses.

Redundancy is in aviation for safety. Nothing wrong with that. The sub builder that died going to see the Titanic thought he had good enough was good enough figured and built too. He had paying passengers That is the mind set and we must flow to change it when needed. Flexible…Adaptive. The fuses in the OP system appear to been Victron approved. Again Victron approved. He followed Victron manufacturer recommendations. That needs to be stressed. The OP followed advice of manufacturer. Victron won’t change unless sued and forced. That is unfortunate. If they change from law suit then might go out of business with follow up civil law suitS. Plural. Might make it so only authorized dealers can purchase. No DIY Sales could result.

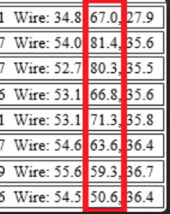

There is Type K copper with the yellow pvc covering.

These builders wanted save money. Profit. Csst is cheaper and thin. Deemed safe even though reports and fire inspectors see other wise. It is the world we live in.

PPL are cheap shhhhsss I know better and have an ANL fuse in my system however a “T” class fuse is on the way. This post reaffirmed my change in decision. I had a conversation with a poster on chit chat about fuses and victron 58v fuse in particular around same time as this post. He is building a 48v golf cart. Coincidence. I’ve got my factory packed batteries in a metal cabinet with wheels….for a reason. Might roll it down the hill. . I kept it small. Emergency back up.only…..btw gas inverter generators fail all the time too.

As did inverter welders.

GE evo ac locomotive have 36 HUGE igbt monsters - fiber optic controlled with back up comm and square fuses …..these were for main traction motors and they still fail. Make glorious melted mess. Nightmare for electricians change out melted buss bars on them. Risk of back injures due to heavy igbt weight…out of position work. Sometimes result of software glitch. Fiber optics cable kinked. Lot of field R&D. Everything is not nailed down and exact. No matter what we tell ourselves.

Likewise We are in effect R&D field techs testing this home power generation storage - equipment long term. We assume the risk. We allowed it into our homes as risk but supposed control safe with practices. We also drop our guard vs vigilant to be on look out smug in ourselves - comfortable. About that time is when we get a bite…. Or feel the burn.

There is a fresh post on this forum of a bms fire most likely from lightning hitting inverter. Fused breaker. Got bms too but bms is getting fault due to name - DALY by some reading and responding. So…. They fail too but lightning hitting inverter most likely started all of it. My factory pack batteries have bms on each 12 volt battery with blue tooth and NOW would not have batteries without blue tooth to monitor. My system is small on purpose. There are also limits to batteries.

Batrium seems like excellent idea for alerts. I am not saying do away with it. Just in addition might be advisable. Of course cheap bms could be the source of problems too. So what now? The real and only safe solution is dump the home system. Then when grid goes down live 19th century style. Must of been a reason we don’t go back to living like that?

I am amazed someone did ask if the Tesla was plugged up and blame it for the OP.

Ppl get mad at me for my opinion - they are fragile ego monsters …my opinion is just that opinion… sometimes ppl are very ignorant as are we all at one time… me initially using anl fuse in my when know better is on me ..stupid……extreme sports. We have to be a critic of things and ourself is a good place to start … we can become the enemy of better if we don’t. NOW Those bean counters wanting those GE fuses done away with were greedy self serving pricks

why I stay on chit chat.

Molten copper cut through this like hot knife through butter but …it will give very limited fire break ….these are sealed batteries placed in a metal cabinet. Notice it says “maximum 4 x 100ah batteries in parallel for 400Ah.” ‘’Maximum 4 in series for 48 volt 100Ah.”

Someone might think they could have 4s4p. Not addressed. But why are they limited to ~20k? Hmmm… OP had 100kWh of cells. Maybe need actual arc chute contactors as design with arrestor - arc chutes that can handle all that voltage and amps dropping out under load.

We built special heavy metal containers to house contactors…for locomtoives. Keep it away from ppl. Pplcostalot of money when hurt or killed….law suits. I tend think it is best to let the manufacturers argue for their products. We can endorse but why argue? I know we are tribal….

No one got hurt or killed in this post was good over all thing. One of problems for toroidal transformer inverters are their ability to go above and beyond 3x surge ability. Harder to fuse. Bigger wires. Notice my Transformer pic next to name.

You can’t do this with high freq. transformer

These idiots have a ~$4000.00 fuse playing with it. Spoiler they are just using it for visual. The transformer they are using is show of capable power. ~9.6million views. Victron is low freq.

Good luck.