OP was lucky in older post he stated his belgium insurance covered him. I wonder are they still covering him.

They will.

They did that as part of a WEF GLOBAL DEAL to my understanding

Different ICC (International Chamber of Commerce).

OP was lucky in older post he stated his belgium insurance covered him. I wonder are they still covering him.

They did that as part of a WEF GLOBAL DEAL to my understanding

Yes there's a remote trip versions of the MNEDC175 and 250 models, RT at the end of the name, currently on sale for $107, a small difference from the regular 250A model with remote trip for $93.@Hedges mentioned some of the midnite breakers can be remote tripped. Those seemed really interesting for some of this sort of thing.

I really like the 10x10 shipping container... The wood floor could be removed then pour concrete into it from the outside, or leave the wood and put durock and ceramic tiles on the floor. So it would become part of the foundation. I may have to look into those when the time gets closer.

www.stellavolta.com

www.stellavolta.com

Good vendor, I bought from them before. Excellent shipping time.Yes there's a remote trip versions of the MNEDC175 and 250 models, RT at the end of the name, currently on sale for $107, a small difference from the regular 250A model with remote trip for $93.

MidNite Solar MNEDC250RT Remote Trip Circuit Breaker 125VDC

Shop now for MidNite Solar MNEDC250RT Circuit Breaker 250A 125VDC. Remote Trip breaker for use with our Battery Disconnect module and the Rapid Shutdown system.www.stellavolta.com

Part the issue in these discussions is extended operational time and individual experiences. I agree it's a cool discussion / thought experiment to be able to 'take a battery offline' but for me, the 1st battery was established 6years ago, have added 8 more, and haven't touched any of them once online. My experience has been that healthy batteries just don't need extraordinary on/off line capabilities if you're goal is to simply have a working powerwall.

But as I often say - no judgements. That's what DIY is all about

Up to 250 cells using longmons - https://wiki.batrium.com/en/product/cell-monitor/longmonI think the batrium looks great for specs. 200+ cells monitoring is fantastic.

Sounds like plan. There were ppl on youtube putting concrete floors in - anchor to ground. Make sure to get a permit if required. $50 and if put in concrete another $50 for foundation permit.@Hedges mentioned some of the midnite breakers can be remote tripped. Those seemed really interesting for some of this sort of thing.

I really like the 10x10 shipping container... The wood floor could be removed then pour concrete into it from the outside, or leave the wood and put durock and ceramic tiles on the floor. So it would become part of the foundation. I may have to look into those when the time gets closer.

Sounds like plan. There were ppl on youtube putting concrete floors in - anchor to ground. Make sure to get a permit if required. $50 and if put in concrete another $50 for foundation permit.Fee grabbers.

I asked this before but will mention it again for everyone was the OP shunt upgraded?

Not sure what amp those 7 strings of batteries were drawing with 3 phase 5000va 230(?) voltage inverters. I figure he is in Belgium and 3 phase charger for Tesla not available here in USA so probably 230v - my guess. Any idea what he was pulling for current? Anyone?

View attachment 214120

I think victron has a 500Amp shunt, 1000amp shunt, and a 2000amp shunt.

As a very rough guess, if each inverter were maxed out at 5000VA, with the batteries at a very low 50V would be 100A each plus losses per inverter, so maybe 350A at a very worst case? But I doubt he was charging at that rate.Sounds like plan. There were ppl on youtube putting concrete floors in - anchor to ground. Make sure to get a permit if required. $50 and if put in concrete another $50 for foundation permit.Fee grabbers.

I asked this before but will mention it again for everyone was the OP shunt upgraded?

Not sure what amp those 7 strings of batteries were drawing with 3 phase 5000va 230(?) voltage inverters. I figure he is in Belgium and 3 phase charger for Tesla not available here in USA so probably 230v - my guess. Any idea what he was pulling for current? Anyone?

View attachment 214120

I think victron has a 500Amp shunt, 1000amp shunt, and a 2000amp shunt.

Lower than 18 inches above ground?I don't think the op ever mentioned which size shunt he was using. I assume max expected current was 700amps, and since the OP was so meticulous with the rest of the build I assume he had a proper sized shunt.

Here in a county outside of city limits a small structure (under 120sqft) without any plumbing or electrical and lower than 18inches above ground doesn't need a permit. So the 10x10 would work fine as long as the outside diminsions are under 10x12. I am assuming it is 10x10 outside and smaller inside.

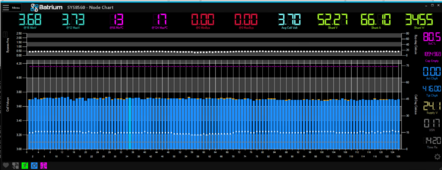

Look at them now and then. After the 6+ years in mild ambient conditions I've gained enough confidence that I don't worry about them physically day by day. Monitoring (Batrium + Camera) + data history for trends is sufficient to alert me to trouble for now. Maybe after 10 more years and I start to get serious, uneven capacity degradation?A few questions -

What sort of regular maintenance and inspections do you do for your battery strings?

All on, all the time. Not sure why I'd want to 'cycle through them' other than some kind of individual battery capacity testing. Individual battery testing has not been needed so far... year 6+ and ongoing.Do you turn them all off at once or one at a time and cycle through them?

All is breaker'ed and labeled (see below). All breakers off and the system defaults to grid / becomes inactive. Order of on/off doesn't matter + individual components will shut off appropriately on their own if necessary.Do you have written instructions for the maint so someone else could do them if you were out of town and/or incapacitated?

Yes but the only one who's used it is me. The most useful has been the PV wiring arrangement down to the panel level.Do you have documentation on your whole system design?

Quick Disconnects outside at the arrays (required by code). At the control area... labeled Breakers forDo you have documentation on startup and shutdown?

Not on this forum.Did you do a build thread?

Look at them now and then. After the 6+ years in mild ambient conditions I've gained enough confidence that I don't worry about them physically day by day. Monitoring (Batrium + Camera) + data history for trends is sufficient to alert me to trouble for now. Maybe after 10 more years and I start to get serious, uneven capacity degradation?

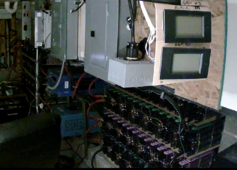

View attachment 214123View attachment 214122

All on, all the time. Not sure why I'd want to 'cycle through them' other than some kind of individual battery capacity testing. Individual battery testing has not been needed so far... year 6+ and ongoing.

All is breaker'ed and labeled (see below). All breakers off and the system defaults to grid / becomes inactive. Order of on/off doesn't matter + individual components will shut off appropriately on their own if necessary.

Yes but the only one who's used it is me. The most useful has been the PV wiring arrangement down to the panel level.

Quick Disconnects outside at the arrays (required by code). At the control area... labeled Breakers for

- PV -> Charge Controllers (required by code - labeled with voltage/current)

- Charge Controllers -> Battery

- Battery -> Inverters.

- 400a shunt-trip for battery bank

- Standard US 240v/120v distribution box / breakers.

Midnite Classic charge controllers don't care about PV vs Battery on/off order - so the overall order of turn on/off doesn't matter. All off and default is grid.

I've trained my wife/extended-family to turn all breakers off to default to grid only.

Not on this forum.

There's no fusing in your batteries? Just the 400A shunt trip to disconnect it?Look at them now and then. After the 6+ years in mild ambient conditions I've gained enough confidence that I don't worry about them physically day by day. Monitoring (Batrium + Camera) + data history for trends is sufficient to alert me to trouble for now. Maybe after 10 more years and I start to get serious, uneven capacity degradation?

View attachment 214123View attachment 214122

All on, all the time. Not sure why I'd want to 'cycle through them' other than some kind of individual battery capacity testing. Individual battery testing has not been needed so far... year 6+ and ongoing.

All is breaker'ed and labeled (see below). All breakers off and the system defaults to grid / becomes inactive. Order of on/off doesn't matter + individual components will shut off appropriately on their own if necessary.

Yes but the only one who's used it is me. The most useful has been the PV wiring arrangement down to the panel level.

Quick Disconnects outside at the arrays (required by code). At the control area... labeled Breakers for

- PV -> Charge Controllers (required by code - labeled with voltage/current)

- Charge Controllers -> Battery

- Battery -> Inverters.

- 400a BMS controlled shunt-trip for battery bank - shuts off 100% of all loads, no battery activity at all.

- Standard US 240v/120v distribution box / breakers.

Midnite Classic charge controllers don't care about PV vs Battery on/off order - so the overall order of turn on/off doesn't matter. All off and default is grid.

I've trained my wife/extended-family to turn all breakers off to default to grid only.

Not on this forum.

It's 18650 - and each of the 12,000+ individual cells are connected to the buss with fuse wire (based on Tesla car battery design). Thus, don't need fusing at the pack or battery level the way one might want for LifePo4 cells.There's no fusing in your batteries? Just the 400A shunt trip to disconnect it?

Ok, I understand now, each cell is fused so no worries at all there for a runaway situation like the OP had.It's 18650 - and each of the 12,000+ individual cells are connected to the buss with fuse wire (based on Tesla car battery design). Thus, don't need fusing at the pack or battery level the way one might want for LifePo4 cells.

If a short were to occur, it's not clear weather the ABB SACE would trip or fuse wires would blow first or both - the entire powerwall would be rendered toothless in short order. It would be a huge 'rebuild' effort

The ABB SACE could trip at 400a overall load (or charge) but the powerwall itself has ~2,000a @ 48v potential so the fuse wire won't burn just for a 400a load. It would take short at a pack or battery or powerwall level for the fuse wires to burn - but that's what they're for.

Certainly puts the fear of god into you when you read something like this. Thankfully he and his family are safe but almost certainly a life changing event. I read about an electronic engineer who had setup lifepo4 batteries from china in germany and house also destroyed but from an explosion.

Investigators still uncertain about cause of 30 kWh battery explosion in Germany

A lithium iron phosphate (LFP) battery system recently exploded in a home in central Germany, preventing police and insurance investigators from entering due to the high risk of collapse. The explosion may have been preceded by off-gassing, but it remains unclear whether an external ignition...www.pv-magazine.com

I think ill start planning to move all my kit out to the shed.

I think the speculation was that the boiler pilot light may have have ignited the outgassing hydrogen from the cell(s).Certainly puts the fear of god into you when you read something like this. Thankfully he and his family are safe but almost certainly a life changing event. I read about an electronic engineer who had setup lifepo4 batteries from china in germany and house also destroyed but from an explosion.

Investigators still uncertain about cause of 30 kWh battery explosion in Germany

A lithium iron phosphate (LFP) battery system recently exploded in a home in central Germany, preventing police and insurance investigators from entering due to the high risk of collapse. The explosion may have been preceded by off-gassing, but it remains unclear whether an external ignition...www.pv-magazine.com

I think ill start planning to move all my kit out to the shed.

Those were pouch cells.I think the speculation was that the boiler pilot light may have have ignited the outgassing hydrogen from the cell(s).

I do not understand the mindset where the Batrium needs to have a BMS on each 48V battery when a Class T is used on each battery.