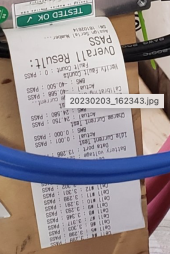

Here is my setup. See pictures.

My main concern is when I put the batteries in parallel at the busbar, is the length of the + cable and - cable. (See pictures, green arrows are areas of concern) my positive cables are much longer than the negative cables. The BMS is my negative cable and goes directly from the battery to the -busbar. 12" blue cable and 12" black cable. The positive cables run up to the breakers and then onto the +busbar, roughly 60". Positive cables are 4/0 from battery to breakers, 2/0 from breaker to busbar.

Negative cables are 2× 4awg coming out of both sides of the BMS.

Every cable that I made is the exact same length for each section.

Is there going to be a problem with the negative wires being shorter than the positive wires?

The picture with the 2 battery cells is just to show location when fully installed, the last picture is how the battery cells will be laid out. There will be 4 total 16s 48v batteries, 2 on each side of the BMS stand. The main positive and main negative will all be facing the BMS stand.

My main concern is when I put the batteries in parallel at the busbar, is the length of the + cable and - cable. (See pictures, green arrows are areas of concern) my positive cables are much longer than the negative cables. The BMS is my negative cable and goes directly from the battery to the -busbar. 12" blue cable and 12" black cable. The positive cables run up to the breakers and then onto the +busbar, roughly 60". Positive cables are 4/0 from battery to breakers, 2/0 from breaker to busbar.

Negative cables are 2× 4awg coming out of both sides of the BMS.

Every cable that I made is the exact same length for each section.

Is there going to be a problem with the negative wires being shorter than the positive wires?

The picture with the 2 battery cells is just to show location when fully installed, the last picture is how the battery cells will be laid out. There will be 4 total 16s 48v batteries, 2 on each side of the BMS stand. The main positive and main negative will all be facing the BMS stand.