A lot of time has passed since I first started this journey. I am reminded of a quote from Thomas Edison. "Genius is 1 percent inspiration, 99 percent perspiration".

Here are some lessons learned from this project:

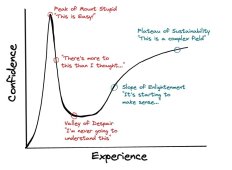

1. Use this forum for information. From a distance everything seems easy, however the closer you get to the details, the more complicated things become.

2. Feel free to get critiques from other users. A double, triple check of a design is helpful for us beginners since we are walking a new path. Admittedly I had to swallow my own pride on more than one occasion. It was worthwhile however because the recommendations were priceless towards the ultimate safety of my project.

3. Make sure to get the right sized lugs. It is tempting to just buy for wire size when you are buying from a supplier. I made this mistake, not knowing better at the time. A properly sized lug will maximize a proper fit so the lug can make a proper connection.

4. Check and check again. Step away from the project to allow a fresh view the next time you look at it. It is amazing the things I have missed in the first inspection.

5. This journey has taken a LOT longer than originally planned. It is easy to look at a few videos from an experienced user and think things will move quickly. My mechanic is very skilled at what he does. When he makes a repair, he makes it easy. That is due to experience. Many of us are at the beginning of this journey. It is natural to make mistakes. The important thing is to learn from these mistakes, thus improving our skill set. I have learned a ton during this process.

6. Look forward to the new tools you will obtain for this project. Having said that, there is professional grade and project grade. It is tempting to pick to pick up a much more expensive tool. Often there is a less expensive option available that will enable you to safely complete the task.

7. Spend the money for quality components. A lot has been said in other threads on this. Having said that, make sure to invest in quality wire, fuses and components. It helps one sleep better at night.

I am opening this to others who might want to share things they have learned from this process.

Hope you have a good day.

Here are some lessons learned from this project:

1. Use this forum for information. From a distance everything seems easy, however the closer you get to the details, the more complicated things become.

2. Feel free to get critiques from other users. A double, triple check of a design is helpful for us beginners since we are walking a new path. Admittedly I had to swallow my own pride on more than one occasion. It was worthwhile however because the recommendations were priceless towards the ultimate safety of my project.

3. Make sure to get the right sized lugs. It is tempting to just buy for wire size when you are buying from a supplier. I made this mistake, not knowing better at the time. A properly sized lug will maximize a proper fit so the lug can make a proper connection.

4. Check and check again. Step away from the project to allow a fresh view the next time you look at it. It is amazing the things I have missed in the first inspection.

5. This journey has taken a LOT longer than originally planned. It is easy to look at a few videos from an experienced user and think things will move quickly. My mechanic is very skilled at what he does. When he makes a repair, he makes it easy. That is due to experience. Many of us are at the beginning of this journey. It is natural to make mistakes. The important thing is to learn from these mistakes, thus improving our skill set. I have learned a ton during this process.

6. Look forward to the new tools you will obtain for this project. Having said that, there is professional grade and project grade. It is tempting to pick to pick up a much more expensive tool. Often there is a less expensive option available that will enable you to safely complete the task.

7. Spend the money for quality components. A lot has been said in other threads on this. Having said that, make sure to invest in quality wire, fuses and components. It helps one sleep better at night.

I am opening this to others who might want to share things they have learned from this process.

Hope you have a good day.

Last edited: