There are some 250uH 20 amp dimmer chokes advertised on e-bay right now that might be ideal.

Would this work?

300UH/25A, ?

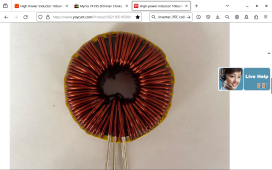

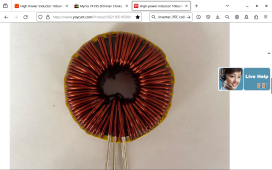

Description

The magnetic ring is selected with an outer diameter of 47mm, an inner diameter of 24mm, a height of 18mm, and a magnetic permeability of 125 060 models.

The 77438 and 77439 series of iron-silicon-aluminum magnetic ring inductors are selected, which have the characteristics of high current and strong anti-saturation, low temperature rise in continuous operation at full current, gentle DC bias, and small high-frequency magnetic loss.

It is very suitable for SPWM inverter output filter inductors, power factor correction circuits (PFC inductors),

DC/DC converter inductors, and grid-connected inverter filter inductors.

. 77438, 77439 series inductors

When the current is small and the inductance demand is large, choose the 77438 series; when the current is large and the inductance demand is small, choose the 77439 series; it can be customized according to the demand.

Inductor size: diameter (length): 55mm width (thickness): 28mm

Foot Spacing: 27mm

5MH/5A, wire diameter 1.0mm, 77438-133T

4MH/8A, wire diameter 1.2mm, 77438-119T

3MH/8A, wire diameter 1.2mm, 77438-103T

2.5MH/10A, wire diameter 1.4mm, 77438-94T

2MH/10A, wire diameter 1.4mm, 77438-84T

1MH/12A, wire diameter 1.5mm, 77439-86T

700UH/15A, wire diameter 1.6mm, 77439-72T

500UH/20A, wire diameter 1.4mm*2, 77439-60T

300UH/25A, wire diameter 1.6mm*2, 77439-47T

100UH/30A, wire diameter 1.4mm*3, 77439-27T

All series are not listed and can be customized according to customer inductance and current.

Introduction to the selection of magnetic core materials: Because the loss and anti-saturation performance of the magnetic powder core material are better than those of the iron powder core (commonly known as: yellow and white ring magnetic ring), and the iron powder core (yellow and white ring) generally can only work at medium and low frequencies (usually 5kHz). below, and the loss is large). Therefore, the magnetic ring inductors designed by our shop are all made of FeSiAl, high magnetic flux or MPP materials (international magnetic core brand CSC or Magnetics). The comprehensive cost performance of the inductors wound with FeSiAl magnetic cores is high; the inductances wound with high flux magnetic cores are small in size, but the price is higher; the inductances wound with MPP magnetic cores are second in volume and low in loss (FeSiAl, high The loss of magnetic flux is also relatively small), but it is expensive. All three materials can operate at harmonic frequencies up to 500kHz.