RCinFLA

Solar Wizard

- Joined

- Jun 21, 2020

- Messages

- 3,565

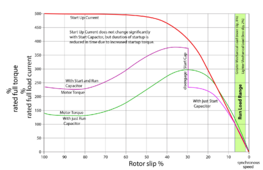

A standard available three-phase VFD drive is not really compatible with a single phase induction motor. They are designed for three phase motors with 120 degs phase difference between phases. I know people have hookup up a three phase VFD using just two phases but it is far from optimum for a single-phase induction motor, having the wrong phase shift and wrong AC voltage for auxiliary winding.I been thinking about dedicated VFD for single phase compressor for few years now. I guess it will still require 3 half bridges same as 3 phase inverter but 3rd half bridge can be made smaller because it would only power start winding. And soft start can be implemented in software.

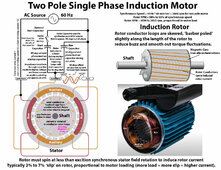

A single-phase induction motor in most air conditioners use a series connected run capacitor to synthesize a second phase AC source to power auxiliary (start) winding.

The proper run capacitor value provides 90 degrees leading phase shift to the auxiliary winding for maximum torque. This simple method of synthesizing a second phase AC source also comes with an impedance transformation. This results in the AC voltage on the auxiliary winding being greater than the main AC supply and run winding. For 240vac mains compressor, the auxiliary winding run voltage is in the ballpark of 300 vac and the auxiliary winding is designed for the higher voltage with more turns of slightly smaller gauge wire than main run winding.