Kuma

New Member

Be sure to know how many RSD's are required per string. SMA RSD's require a minimum of 6, max is 30. Tigo told me 7 is min. AP Systems may be different also. That little detail almost derailed my install...

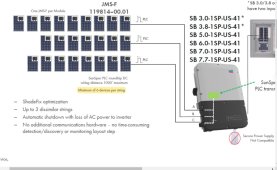

fwiw - I decided to kiss and use all SMA, inverter and RSD. Some of those transmitters are only warrantied 5 or 10 years. SMA RSD have a 25 yr warranty.

fwiw - I decided to kiss and use all SMA, inverter and RSD. Some of those transmitters are only warrantied 5 or 10 years. SMA RSD have a 25 yr warranty.