Symbioquine

Solar Enthusiast

- Joined

- Jul 6, 2021

- Messages

- 432

Hi Folks!

I've been playing with various off-grid systems for a while now, but just starting to get into building my first LiFePO4 system.

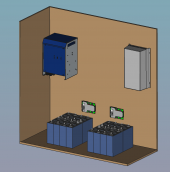

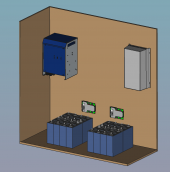

With any building/design project, one thing that really helps me think through the spatial and material requirements is being able

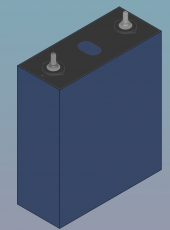

to visually assemble the system before I've cut/fastened/bought any parts. For this, a CAD program is ideal - and being an Open Source

fan, FreeCAD is the flavour of choice for me.

This is a bit of a multi-pronged thread. I want it to;

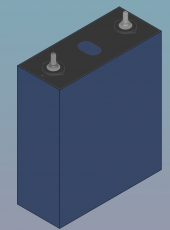

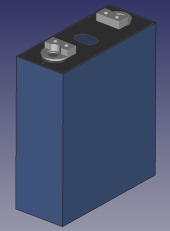

(Obviously, don't blindly trust the dimensions I've used in the model. I've done my best to follow the spec. sheet, but I could have made

errors or your cells could be different.)

Cheers,

Symbioquine

I've been playing with various off-grid systems for a while now, but just starting to get into building my first LiFePO4 system.

With any building/design project, one thing that really helps me think through the spatial and material requirements is being able

to visually assemble the system before I've cut/fastened/bought any parts. For this, a CAD program is ideal - and being an Open Source

fan, FreeCAD is the flavour of choice for me.

This is a bit of a multi-pronged thread. I want it to;

- Start a discussion where folks can share their experiences with Open Source CAD software as a DIY Solar/Energy system design tool. Perhaps those who've had successes can also share screenshots/renders of their finished models to inspire others.

- Solicit ideas for the best way to maintain a community parts library resource. Many companies already provide CAD files for their hardware so these could simply be linked, but other hardware has to be modeled from scratch. My thought is that if we can share low/medium fidelity models of common specific hardware and generic things like breakers/busbars/etc these can reduce the time/effort needed to generate useful 3D system design documents.

(Obviously, don't blindly trust the dimensions I've used in the model. I've done my best to follow the spec. sheet, but I could have made

errors or your cells could be different.)

Cheers,

Symbioquine