Introduction

With the increasing amount of users on the DIY Solar Forum and more people exploring the options to build their own battery packs we've seen common mistakes and dangerous situations occur more frequently - sometimes with disastrous outcomes. While many of the issues we come across have been discussed and resolved in many posts across the forum, this information seems to be spread out or not easily discovered by new members. The goal of this handbook is to set forth a list of basic guidelines and principles with the primary focus on safety even if this might come at the expense of performance. The outcomes of following these guidelines will hopefully limit potential damage to property or even prevent life threatening situations.

Prerequisites

The following are some required tools and knowledge one should have before starting a battery build. We highly recommend having these in place before embarking on a build:

- Digital multi-meter and basic knowledge on use (measuring DC voltage, continuity testing)

- Lab power supply (10A)

- A basic understanding of

Ohms law

- Common tools such as pliers, cutters, and screw/socket drivers (make sure you use insulated handles!)

- A clean workspace, free from clutter

Always wear a pair of gloves and safety glasses while working on batteries. Wear closed shoes, long sleeve trousers and shirts. Take off any jewelry and watches. Make sure you know which terminal of the battery cell is the positive and which one the negative.

LiFePO4 chemistry

This handbook will only consider the use of LiFePO4 cell chemistry. At the time of writing this is the safest chemistry since it does not experience thermal runaway potential that other chemistries exhibit. Note however that even though LiFePO4 is considered safer than others, this does not mean it is 'safe'. Exposure to the electrolyte is not healthy and one should immediately discard any damaged cells. Venting electrolyte can ignite and forms a fire risk. Bloated cells should never be used.

Also keep in mind and respect the amount of energy stored in even a single cell. A typical 280Ah 3.2V single cell can store close to 1kWh of energy - enough to run a typical coffeemaker for a whole hour. Because of the low internal resistance of these cells, shorting them will release this energy very quickly and this can lead to molten metal being thrown around.

Balancing

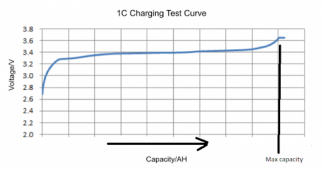

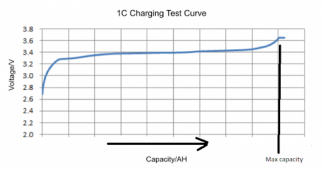

Cell balancing is the process of getting individual cells that are at a different state of charge to the same level. Because of the flat charge/discharge curve, the voltage is not a good indicator for this except at very high or very low states of charge. This is also the reason why just putting these cells in parallel for a day or so does nothing. The goal is to top balance the cells (at high state of charge):

We recommend that top balancing is performed on a per-cell basis. The procedure is:

- Set the voltage on your power supply to 3.6V

- Connect the battery

- Wait until the current drops below 1A

Make sure you use proper cables - use at least 6mm² (10AWG) cable - with ring terminals to connect the power supply to the cell. The cables which come with most power supplies are insufficient, and will cause a large resistance preventing the full current from the supply.

Never change the voltage on your power supply while connected to the cell. It's normal that during this process, the voltage on the supply will drop. Don't try to adjust!

After initially connecting the battery to the power supply, it will most likely go into constant current mode. This also means you will see a drop in the voltage on the supply read-out. This is absolutely normal; do not attempt to adjust this.

Once the procedure is done for each cell then these are balanced. Note that the voltage of the cell will settle back down from 3.6V - this is normal. Please keep in mind that balancing cells is a time consuming process: if one takes a 280Ah cell and assumes this cell is at 50% state of charge, a 10A supply will take 14 hours to fully charge this cell. Patience is key.

BMS

A Battery Management System (BMS) is required to protect your cells from catastrophic failures. A BMS should have at least:

- under voltage disconnect

- over voltage disconnect

- over temperature disconnect

- under temperature disconnect

Make sure the settings of these parameters are correct in the BMS before operating your battery pack in any way. Recommended settings are 3.60V for over voltage and 2.55V for under voltage protection.

A BMS should provide temperature protection and disconnect the battery when the temperature exceeds or drops below a certain value. Typically, one should stop charging when a cell temperature drops to 5°C (41°F) or exceeds 50°C (122°F). Discharge should stop when the temperature reaches -20°C (-4°F) or 50°C (122°F). Please note that 25°C (77°F) is ideal; usable capacity will be impacted on both lower and higher temperatures.

Please note that a BMS is a protection device, a last line of defense to protect your cells. Do not use a BMS for day-to-day operations such as disconnecting loads, turning off charging at battery limits, etc. Under normal circumstances, the BMS shouldn't do anything.

Bus Bars

Because cells can expand and contract during charging and discharging and in mobile applications can be subjected to forces due to movement, terminal stresses can be generated. We recommend using flexible bus bars to connect cells together for this reason. These can be bought, or made with crimp lugs of the appropriate size. Always make sure you consult an ampacity chart to make sure your bus bars can handle the required current. Remember: the lower your battery voltage, the higher the current will be for the same amount of power.

Terminals

At the time of writing most cells come with welded studs. These are recommended. Do not exceed the torque specified by the manufacturer when connecting your bus bars. Do not place washers on top of the terminal, only on top of the bus bar. Serrated nuts are recommended.

Fixture

LiFePO4 cells should be mounted in a fixture so that movement of cells is minimized. It is recommended to put a sheet of insulation (e.g. neoprene) between each cell in the fixture and to the sides of the fixture. Never place cells in a metal fixture without insulation.

Fuses

Class-T fuses are recommended per battery pack in all cases. Size your fuse 25% higher than what you intend to pull. Remember, fuses protect wiring, not equipment. Fuses should be installed on the positive lead of the battery.

Disconnect

An appropriately sized disconnect switch is recommended to be installed on each battery pack and should be installed right after the fuse on the positive lead on the battery. It is recommended to use a manual, mechanical switch of sufficiently rated current with an appropriate safety margin.

Cables

Appropriate wire sizes must be chosen at all times. Consult an ampacity chart and make sure you do not exceed what your cables are rated at. Use stranded, flexible cables with proper insulation. We recommend using only specific cable indicated as 'battery cable' or sometimes 'welding cable'.