Why would you think it is a DIY terminal lug? It's totally legit and I have it all listed out on my Single Line Diagram with links and specs to every single item in the installation. All that was required to even get the project started. If you are curious, it is the "Nader DC Circuit Breaker | 60V 200Amp" from signature solar. That sort of goes to my point about two way communications (Q&A) with the inspector. If he "thought" it was DIY, then he should have either asked me...or referred back to the documentation I provided. Simple stuff.I can sure see why the inspector thought that lug was something DIY.

A multiple pole breaker with multiple tap busbar stuck in it and adapted to large cable.

It is DIY by the company which got it through UL listing. If the breaker itself is actually UL listed. Or is it listed somewhere else in the world, and the assembly containing it was UL listed?

What amperage, voltage, AIC rating is it?

A single Midnight/Carling 175A or 250A breaker would do the job an fit battery cable in the lug.

Midnight also sells multiple pole breakers with ganging connector. They seem a bit goofy.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Failed Inspection - need some advice and guidance for NEC 690 infractions.

- Thread starter meager

- Start date

Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 21,303

Because it looks like a goofy addition to a commecialy made breaker. And I think it is (by someone.)

Data sheet is for a multi-pole breaker up to 125A

Who added the lug which parallels poles and gave it a 200A rating?

Where is the UL listing?

If delivered as part of an assembly that was UL listed, that should cover it.

I wonder what spread between "must not trip" and "must trip" it gives? What range of current imbalance does it have between poles?

Data sheet is for a multi-pole breaker up to 125A

Who added the lug which parallels poles and gave it a 200A rating?

Where is the UL listing?

If delivered as part of an assembly that was UL listed, that should cover it.

I wonder what spread between "must not trip" and "must trip" it gives? What range of current imbalance does it have between poles?

I had one of those inspectors once. We had to get a field UL listing on a piece of equipment as installed to shut him up. His concern was quite esoteric about a code change, but there were no products on the market that had caught up to it. (HVAC unit)...the inspectors job is to inspect...

We went the field UL route because of liability if we tried to accommodate him by replacing the unit... even though it was more money. I think it cost about $40k on equipment that originally cost $30k, but if it was removed or modified we would have an E&O claim for significantly more. Inspector was a pain for the duration.

Oddly on the next project I worked with him on he was completely cordial and professional with no "surprises."

Zwy

Emperor Of Solar

I'm confused because when looking at this breaker on SS, it shows a lug on each side. Your photo shows a crimped terminal on top and the screw lug on the bottom (lug is circled).

My guess is the inspector wanted a crimped terminal on both top and bottom. You already modified the breaker with the crimped terminal, whether that affects the UL listing is another matter.

My guess is the inspector wanted a crimped terminal on both top and bottom. You already modified the breaker with the crimped terminal, whether that affects the UL listing is another matter.

Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 21,303

That modification to terminals is apparently by SS/EG

signaturesolar.com

signaturesolar.com

Is it UL listed? I'm not finding mention of that.

Not saying it is wrong to add lugs, which someone appears to have done, and I don't think it will leave a cable unprotected. Might trip below desired current.

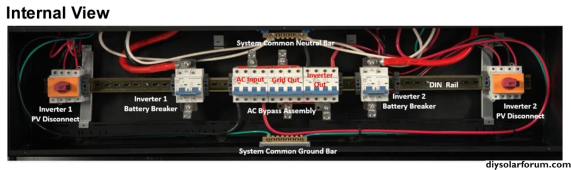

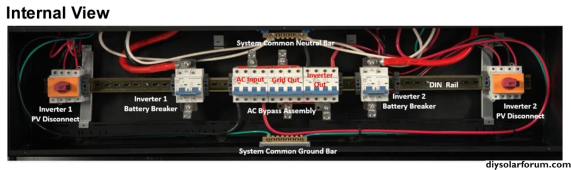

EG4 Load Center PDP for EG4 6500EX | 120/240VAC

Signature Solar provides solar panels, off-grid solar systems, grid-tie, and hybrid systems. Quality solar inverters, bifacial solar panels, complete solar kits, solar batteries. Featuring brands such as EG4 Electronics with their solar battery, LifePower4 and EG4 LLifePower4 and EG4 LL

signaturesolar.com

signaturesolar.com

Is it UL listed? I'm not finding mention of that.

Not saying it is wrong to add lugs, which someone appears to have done, and I don't think it will leave a cable unprotected. Might trip below desired current.

Zwy

Emperor Of Solar

That modification to terminals is apparently by SS/EG

I think the inspector wanted a crimped terminal instead of the screw type lug for fine wire on the bottom of the breaker. I can see his point, repeated heating cycles with fine wire could lead to resistance or the cable to fall out of the lug. I know what I would have done, I would have put a crimped terminal on the battery cable and there would not have been a hassle. In addition, the crimped terminal means an airtight terminal and prevents oxidation of the cable. That said, the terminal on my ABB breaker for my battery box are not crimped lugs. They are however the clamp type which would be a better choice for fine wire.

Screw type would be fine for THHN or similar. Not so much for fine wire like most battery cable.

I was unaware SS/EG4 was building a panel like that.

Zapper77

Renaissance Man

- Joined

- Jul 23, 2022

- Messages

- 2,343

What about using a tinned ferrule?I think the inspector wanted a crimped terminal instead of the screw type lug for fine wire on the bottom of the breaker. I can see his point, repeated heating cycles with fine wire could lead to resistance or the cable to fall out of the lug. I know what I would have done, I would have put a crimped terminal on the battery cable and there would not have been a hassle. In addition, the crimped terminal means an airtight terminal and prevents oxidation of the cable. That said, the terminal on my ABB breaker for my battery box are not crimped lugs. They are however the clamp type which would be a better choice for fine wire.

Screw type would be fine for THHN or similar. Not so much for fine wire like most battery cable.

I was unaware SS/EG4 was building a panel like that.

As long as it is UL 486 A/B listed and you use an appropriate crimper, probably so.What about using a tinned ferrule?

Honestly, if I had used a crimped terminal lug, he would have popped me for it not being UL 486 A/B listed. He wanted to see something printed clearly on whatever method I used. I’m telling you, this was a never ending cycle until his boss man put an end to the madness. I do feel sorry for others in this county because they have a long uphill battle.I think the inspector wanted a crimped terminal instead of the screw type lug for fine wire on the bottom of the breaker. I can see his point, repeated heating cycles with fine wire could lead to resistance or the cable to fall out of the lug. I know what I would have done, I would have put a crimped terminal on the battery cable and there would not have been a hassle. In addition, the crimped terminal means an airtight terminal and prevents oxidation of the cable. That said, the terminal on my ABB breaker for my battery box are not crimped lugs. They are however the clamp type which would be a better choice for fine wire.

Screw type would be fine for THHN or similar. Not so much for fine wire like most battery cable.

I was unaware SS/EG4 was building a panel like that.

Yes....but No. I have my property completely gated off so nobody can get in and be nosey (legally). The improvements may require permits, but what one doesn't know doesn't hurt them. I don't live in a "residential" area at all. My nearest neighbor is about a mile away.Now that your inspection is approved, will further iterations need approval?

TomC4306

Solar Obsessive

Put the controller in an enclosure connected to the raceways?This post just made me realize I'm not sure how a Victron charge controller can pass since there is no way that I can think of to have the 30VDC+ PV wire enclosed in a metal raceway. The controller expects only the cables themselves to entire the bottom of the controller.

Or run you PV wire into a common metal junction box if indoors, then split them out in pairs via rigid metal conduit or flexible metal conduit. It looks like the victron will accept probably 3/4" for each PV string?Put the controller in an enclosure connected to the raceways?

Zapper77

Renaissance Man

- Joined

- Jul 23, 2022

- Messages

- 2,343

Did the NEC say something like Metal to the first means of disconnect for PV?Or run you PV wire into a common metal junction box if indoors, then split them out in pairs via rigid metal conduit or flexible metal conduit. It looks like the victron will accept probably 3/4" for each PV string?

zanydroid

Solar Wizard

I think the first disconnect is an old rule:

690.31(D) Direct-Current Circuits on or in Buildings.

Where inside buildings, PV system dc circuits that exceed 30 volts or 8 amperes shall be contained in metal raceways, in Type MC metal-clad cable that complies with 250.118(10), or in metal enclosures.

www.electricallicenserenewal.com

NEC 2017 requires metal to the first disconnect, NEC 2020 and later require all of PV system dc circuits in metal raceways and enclosures.Did the NEC say something like Metal to the first means of disconnect for PV?

From the moment PV DC (above 30V) crosses the threshold to the interior, it needs to be in metal. I started my transition just outside of the power shed with a metal LB connector and it just continues throughout the interior of the shed. I know it says metal to the first disconnect, but just to be safe, you might as well take it all the way to your inverters if possible. Better safe than sorry IMO.Did the NEC say something like Metal to the first means of disconnect for PV?

Zapper77

Renaissance Man

- Joined

- Jul 23, 2022

- Messages

- 2,343

Residence or a non-residential Accesory Building?From the moment PV DC (above 30V) crosses the threshold to the interior, it needs to be in metal. I started my transition just outside of the power shed with a metal LB connector and it just continues throughout the interior of the shed. I know it says metal to the first disconnect, but just to be safe, you might as well take it all the way to your inverters if possible. Better safe than sorry IMO.

zanydroid

Solar Wizard

The 690.31 excerpt from my post says building.

For my installation, it is an "out-building" located 10 feet from my home for use as a solar power shed. I would agree with @zanydroid that the code says "building". I wouldn't go too far in the weeds and try and draw your own conclusion as to what that means. If the "building" can catch fire, it very likely needs to be enclosed in metal and protected as such. My limited experience tells me that there really isn't any room for your definition of this or that. With the use of an inexpensive tube / pipe cutter, it really is quite an easy installation. The key is to do it right the FIRST timeResidence or a non-residential Accesory Building?

Similar threads

- Replies

- 1

- Views

- 382

- Replies

- 5

- Views

- 333

- Replies

- 75

- Views

- 6K

- Replies

- 8

- Views

- 389

- Replies

- 25

- Views

- 761