Detritalgeo

New Member

Further to above.. They are not yet selling the floor or wall brackets. Maybe their support people can give us an idea when they may be availableAre these ok to use in vertical orientation - front face pointing up?

Further to above.. They are not yet selling the floor or wall brackets. Maybe their support people can give us an idea when they may be availableAre these ok to use in vertical orientation - front face pointing up?

How to wire RUiXU Server Rack battery RX-LFP48100 wtih Victron Multiplus -Ⅱ Inverter - - YouTubeAfter contacting support, apparently their API's are under NDA. Apparently they don't have a tool for any kind of monitoring. I asked support specifically about cabling to the EG4 18KPV/12 but received a rather non-descript answer. Since I'm not signing an NDA I'll try and reverse engineer something based on the Victron or EG4 published specs. I mean really, ... an NDA to talk to the BMS on a battery from a Chinese company that likely 'borrowed' the design to start with. . .

But it's a super-secret request for the current SOC on the batteries, nobody else has that... Good grief.

No I don't but , Will Prowse spoke about the cable on one of his reviews on the RUiXU Server Rack batteryDo you know the manufacturer and/or model of the battery connector?

It is the Amphenol SurLok system for HV connections.. or at least it looks like it. There are also some Chinese groups making the same type of single pole connector, Futronics for example (which is what AOLithium uses I suspect).Do you know the manufacturer and/or model of the battery connector?

Did you try their technical support email or the sales email?Thanks all helping me to find out what battery connector it uses.

Now if Ruixu support could be this helpful to let me know what it uses instead of just stop answering my emails when asking them.

I was just told in email that they do not have any inventory of 2 AWG cable.Waiting for them to reply to my request to get cables using AWG 2 instead of 4.

That is what I figured as well, and it would probably void the warranty to replace them. That really is too small for a battery BMS that can deliver 100A. Short leads of 4awg from the terminal to the bus bar in the rack would probably be okay, but I do not have a rack or bus bars.As the manufacturer of the cable can’t do AWG 2 then I believe the plug they use is the 5.7mm that can maximum fit AWG 4.

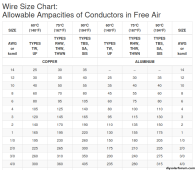

100A (5KW) would probably be ok with #4 in free air, but you'd probably want it to be a short interval. A 100A capable battery is not normally designed to pump 100A sustained output. Most of these units are engineered for 50% duty (50A). You can run them higher, and most quote 150A for a short burst, but ideally they perform better at lower discharge rates.That is what I figured as well, and it would probably void the warranty to replace them. That really is too small for a battery BMS that can deliver 100A. Short leads of 4awg from the terminal to the bus bar in the rack would probably be okay, but I do not have a rack or bus bars.

While all that is true, engineering things safely doesn't care much about how it operates under normal conditions. You >could< use a 30A breaker on 14 gauge wire too, because normally, it would be just fine, but you and I both know we don't always have control over the load. Unfortunately, that makes it something to work around on an otherwise pretty solid looking battery system. Will know soon, one on order.100A (5KW) would probably be ok with #4 in free air, but you'd probably want it to be a short interval. A 100A capable battery is not normally designed to pump 100A sustained output. Most of these units are engineered for 50% duty (50A). You can run them higher, and most quote 150A for a short burst, but ideally they perform better at lower discharge rates.

While all that is true, engineering things safely doesn't care much about how it operates under normal conditions. You >could< use a 30A breaker on 14 gauge wire too, because normally, it would be just fine, but you and I both know we don't always have control over the load. Unfortunately, that makes it something to work around on an otherwise pretty solid looking battery system. Will know soon, one on order.

It's under the NDA...Thanks all helping me to find out what battery connector it uses.

Now if Ruixu support could be this helpful to let me know what it uses instead of just stop answering my emails when asking them.