Texas-Mark

Solar Addict

- Joined

- Aug 4, 2021

- Messages

- 1,408

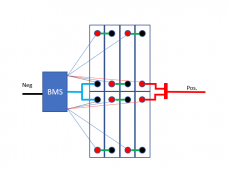

For simplicity, assume a 12V battery bank composed of 8 cells.

Since some people have said that it is not ideal to have cells in parallel (for BMS monitoring), and that it is better to monitor cells individually, how do you do that with 8 cells. Is it possible with a single BMS?

Since some people have said that it is not ideal to have cells in parallel (for BMS monitoring), and that it is better to monitor cells individually, how do you do that with 8 cells. Is it possible with a single BMS?