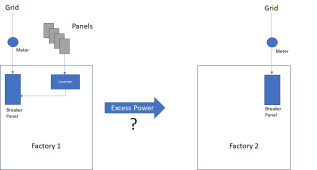

Our factory have a large solar array and for 8 months of the year export a significant proportion of the generated power back to the grid without being paid anything for it. The factory next door use a large amount of power which is all supplied from the grid.

We would like to export our surplus power to them but as we are on separate grid connections we could not have an AC connection.

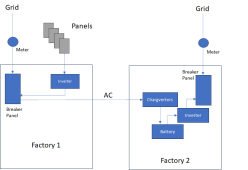

So I am thinking if we had a large hybrid inverter to take our surplus power and convert it to DC then export this next door then have a large ordinary inverter at their premises convert it back to AC for them to use is this feasible?

We would like to export our surplus power to them but as we are on separate grid connections we could not have an AC connection.

So I am thinking if we had a large hybrid inverter to take our surplus power and convert it to DC then export this next door then have a large ordinary inverter at their premises convert it back to AC for them to use is this feasible?