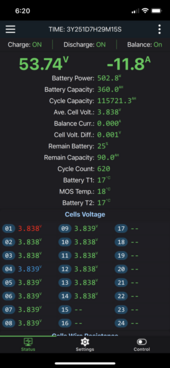

I have a JK-BMS Hardware version 3, yes, it is 4 years old now. When the only thing charging it was my XW-Pro inverter. it would routinely reset to 100% SoC without a problem. But since I added the DC charge controller, both the BougeRV and now the Victron, I see the SoC creeping lower and lower with each charge cycle. It got to the point where it was hitting near 0% with the cell voltages still over 3.6 volts on Li NMC cells. My system is all working on voltage control, so this SoC error is not really a problem, but it is annoying.

Up until about 4 months ago, the cycle count looked pretty accurate. Each time I cycled 360 amp hours in and back out of the battery, it would add one cycle count. I read another thread on here, and watched one of Andy's (Off Grid Garage) videos where they trigger a reset to 100% by lowering the cell over volt disconnect. I tried it, and it worked, as soon as it went into cell over voltage, the SoC jumped right up to 100%, all good, right?

NOPE. The SoC was showing under 5% before that charge cycle, and it only took 185 Amp Hours or so before I triggered the cell OVP. Since then, the cycle counter jumped up to nearly double and is counting up twice as fast. It now adds a cycle eah time I cycle just 185 amp hours instead of 360 amp hours.

It evidently "Learned" a new battery capacity because of the short cycle to 100% SoC. Again, the numbers don't really bother me as I am not using them directly. But it was nice to see a quick read of how hard the battery was working. Now the numbers look bad like I am using up the battery nearly twice as fast.

View attachment 203777

Here it is showing 620 cycles, but based on the actual capacity and amp hours cycled, it should only be 52% of that, or about 322 cycles so far. But the entry still shows my 360 amp hours entered, not the 187 or so it calculated.