I've been out of the panel purchasing game for a while, so I'm cruising all of the consumer grade retailers I've known over the years and finding something curious.

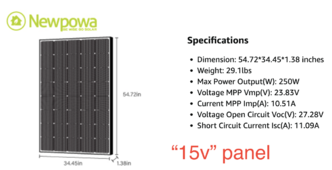

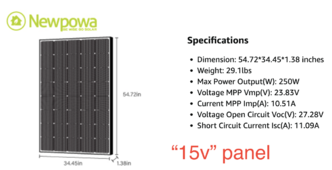

Some are offering "9V" panels, 18v Voc. Or "15v" panels, 27v Voc.

Can anyone theorize on why this is a thing? Seems a little far fetched to think they're doing it so people can redesign their entire systems at the panel level and not have to upgrade their charge controller to hit some very narrow voltage tolerance number, for instance... or work within the bounds of some crummier "solar generator" units.

And actually, in looking at clown shoes Jackery, two 9v panels in series wouldn't work, and the 15v alone wouldn't work either. So who are they trying to please by rattling the standard?

Some are offering "9V" panels, 18v Voc. Or "15v" panels, 27v Voc.

Can anyone theorize on why this is a thing? Seems a little far fetched to think they're doing it so people can redesign their entire systems at the panel level and not have to upgrade their charge controller to hit some very narrow voltage tolerance number, for instance... or work within the bounds of some crummier "solar generator" units.

And actually, in looking at clown shoes Jackery, two 9v panels in series wouldn't work, and the 15v alone wouldn't work either. So who are they trying to please by rattling the standard?