42OhmsPA

What's in a title?

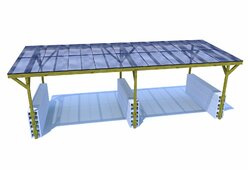

I like it. I'm sure it would be sturdy but I'd add more ballast. ..

How much additional weight would you gain using solid blocks instead of cinder blocks on the layers that don't have beams running through them?

I'd bet that would add a significant amount, you could also add a row or two in the front and back to give it some extra resistance to tipping. (I'm not an engineer and would still run some numbers but I think it would be plenty sturdy, if wind tipped it you have bigger issues to deal with)

I've seen the wind do some crazy things and I don't even live in a windy area.

How much additional weight would you gain using solid blocks instead of cinder blocks on the layers that don't have beams running through them?

I'd bet that would add a significant amount, you could also add a row or two in the front and back to give it some extra resistance to tipping. (I'm not an engineer and would still run some numbers but I think it would be plenty sturdy, if wind tipped it you have bigger issues to deal with)

I've seen the wind do some crazy things and I don't even live in a windy area.