I don't want to argue with the 'BoobTube Degree' types, so this is what *I* personally do.

You can't argue with what anyone does when they aren't recommending everyone to do it.

If you get some ideas, then maybe that's a good thing...

*I* put heavy, glue filled heat shrink tubing on anything exposed, like the spaces between terminals on buss bars, wire sockets on terminal ends/lugs, ect.

For

@Santa, since the cat is out of the bag, is something designed specifically for this application.

Commonly used on big trucks that can draw several hundred Amps (not Amps per hour/Ah)

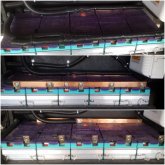

With a 125A 'Last Ditch' fuse between each battery and positive side of harness (on top of circuit breaker/disconnect between batteries and inverter) those very expensive batteries are protected!

Since Battle Born batteries have shrouded terminals, you have to reach into that protected area to make contact.

Without 'Bunny Ear' cables hopping over the BMS humps on the batteries, I used a solid electrical brass extension that will conduct over 200 Amps to reach from cable terminals to battery terminals.

Once these extensions are installed, simply heat shrink for insulation and trim off the excess, since they won't have to be removed for the life of the battery in most cases.

While I show common steel nuts for fitting, this will get to Santa with BRASS NyLoc lock nuts in all positions.

No sense in giving away the connection/conductivity potential of a 3/8" electrical brass fastener.

Same brass the Battle Born batteries use, and in 3/8", it's almost a 200A conductor on it's own.

As the terminals age, they will tarnish (corrosion) so they will become less effective as electrical conductors, adding the extra capacity for the cost of a brass bolt/nut/copper or brass washer, there is no excuse not to use these.

With exception of the High Amp Terminals and Welding Cable between battery harness and inverter, all parts are 'Off The Shelf'.

The high amp/heavy terminal ends need to be crimped onto the welding cable, so they take some work other than screwing parts together.

Since it's all common, and all intended for common applications, the price is very reasonable to protect those batteries that are almost $1,000 each.