fmeili1

Solar Enthusiast

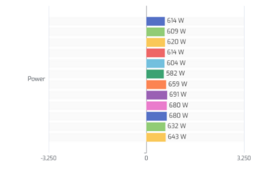

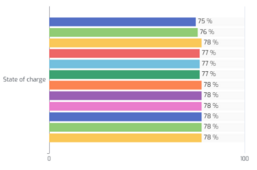

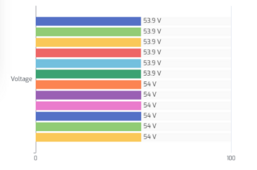

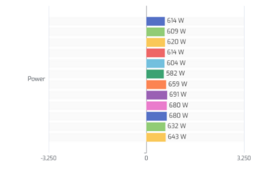

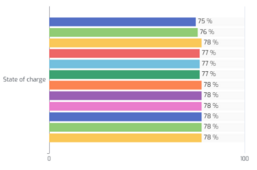

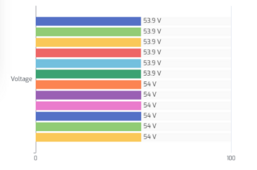

I also monitor very closely the battery situation. All 12 batteries are very close regarding their SOC and voltage. Also, while charging/discharging they all take/give the same wattage of power. Here is an example while charging with 7.6kW:

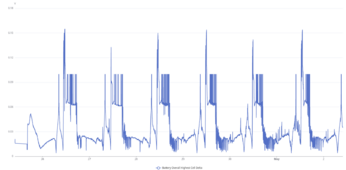

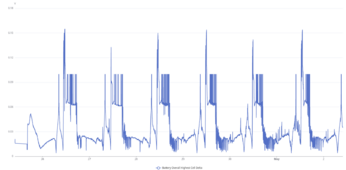

I also monitor the max. highest cell delta over all batteries in my smart home system. The following chart shows the max. delta over the last 5 days (SolarAssistant only gives me the max/min/average cell delta per battery and not for each cell inside each battery, the these are all max values):

The max. cell delta will usually stay below 30mV and only rises for a short time up to 150mV just before they are fully charged in bulk mode (with about 0.15C) and while keeping them full for the rest of the day the max. delta will be between 60mV and 90mV (float?). As soon as the batteries gettting discharged again (from around 100% SOC), the max. delta will again drop below 30mV. I think this behavior is ok - but not 100% sure! As far as I understand, it's ok if the max. cell delta will be much higher just before bulk charging ends...

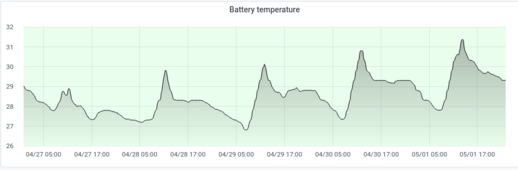

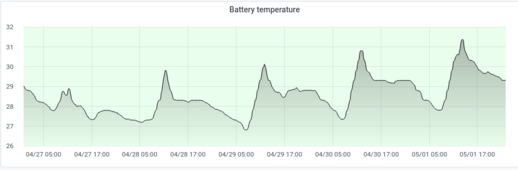

This is the battery temperature chart over the last 5 days:

Update

Btw. I'm using 55.2V absorption charge voltage and 53.6V float charge voltage

I also monitor the max. highest cell delta over all batteries in my smart home system. The following chart shows the max. delta over the last 5 days (SolarAssistant only gives me the max/min/average cell delta per battery and not for each cell inside each battery, the these are all max values):

The max. cell delta will usually stay below 30mV and only rises for a short time up to 150mV just before they are fully charged in bulk mode (with about 0.15C) and while keeping them full for the rest of the day the max. delta will be between 60mV and 90mV (float?). As soon as the batteries gettting discharged again (from around 100% SOC), the max. delta will again drop below 30mV. I think this behavior is ok - but not 100% sure! As far as I understand, it's ok if the max. cell delta will be much higher just before bulk charging ends...

This is the battery temperature chart over the last 5 days:

Update

Btw. I'm using 55.2V absorption charge voltage and 53.6V float charge voltage

Last edited: