@Keith_PDX

It's hard to say, your 150Ah models have a complete other pole layout than my 200Ah and may have another chemistry inside.

The bolts and nuts from yours are the same like my "bad/old" batteries but I prefer this stronger bolts because M4 screws are really not strong enough.

When I bought the second set after 1 month, BLS told me they could not deliver M6 anymore. The new types were all M4 "to protect the poles"...

I guess that they switched to M4 because expanding batteries in series, next to each other, may generate large forces on the link sheets and the poles may break with the strong M6 bolts.

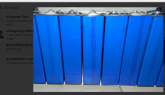

Important: If you setup your 8S bank, make sure there is at least 2mm space between every cell to allow for cooling and expanding.

If you can't because the link sheets are too short then enlarge the holes in the sheet.

Don't put your batteries in a firm box or so. Make sure they can "move" freely.

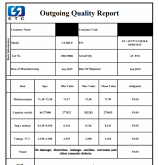

I would advice you to do a capacity test when they are new and unused. Then you have a reference for later.

Charge individual cells to 3.65V and discharge to 2.55V measuring the AH / Wh.

Make sure you never discharge lower than 2.55V. The voltage may drop rapidly at low SOC and your cell will expand/degrade quickly.

After testing you have to charge it back to the same SOC as the other cells before you operate in 8S.

You can use an electronic load to discharge and measure the Ah /WH. Can buy cheap from ALI.

It's also very useful to test solar panels and other batteries.

If you don't have already, I suggest you buy a good DC Amp clamp meter. You will really need it.

I use Bside ACM91, 100A DC+AC + Ohm+freq and voltmeter (from Ali)

It's hard to say, your 150Ah models have a complete other pole layout than my 200Ah and may have another chemistry inside.

The bolts and nuts from yours are the same like my "bad/old" batteries but I prefer this stronger bolts because M4 screws are really not strong enough.

When I bought the second set after 1 month, BLS told me they could not deliver M6 anymore. The new types were all M4 "to protect the poles"...

I guess that they switched to M4 because expanding batteries in series, next to each other, may generate large forces on the link sheets and the poles may break with the strong M6 bolts.

Important: If you setup your 8S bank, make sure there is at least 2mm space between every cell to allow for cooling and expanding.

If you can't because the link sheets are too short then enlarge the holes in the sheet.

Don't put your batteries in a firm box or so. Make sure they can "move" freely.

I would advice you to do a capacity test when they are new and unused. Then you have a reference for later.

Charge individual cells to 3.65V and discharge to 2.55V measuring the AH / Wh.

Make sure you never discharge lower than 2.55V. The voltage may drop rapidly at low SOC and your cell will expand/degrade quickly.

After testing you have to charge it back to the same SOC as the other cells before you operate in 8S.

You can use an electronic load to discharge and measure the Ah /WH. Can buy cheap from ALI.

It's also very useful to test solar panels and other batteries.

If you don't have already, I suggest you buy a good DC Amp clamp meter. You will really need it.

I use Bside ACM91, 100A DC+AC + Ohm+freq and voltmeter (from Ali)