AlaskanNoob

Solar Enthusiast

- Joined

- Feb 20, 2021

- Messages

- 953

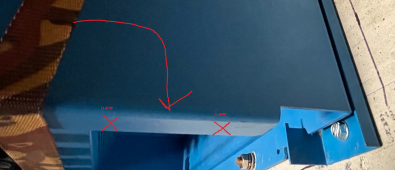

Finally putting these blue boxes on the wall. Precious little info on mounting this super heavy Quattro 15K though. It comes with some screws for the bracket (though we're missing one) and it has side bolts that bolt through side part of the bracket into the Quattro.

I'm just wondering, with my wall consisting of 3/4" plywood and 1/2" cement board, is that going to be enough to hold this beast up on the wall? The bracket won't be installed into studs, just that.

Also this document below shows 6 total holes in the bracket (3 each side) that are not countersink for screws, but it never explains what if anything is supposed to be inserted through those holes.

https://www.victronenergy.com/upload/documents/Quattro-48V-15000VA-230V.pdf

I'm guessing I need to find what goes into those six holes before trying to put this biggum up on the wall.

From this video, this guy seems to have only used those holes to attach the bracket to his cement board. Then he put his cement board up against his wall and used the screws to hold it up. It's too late for us to use those holes on cement board though, since that board is already up on the wall.

I'm just wondering, with my wall consisting of 3/4" plywood and 1/2" cement board, is that going to be enough to hold this beast up on the wall? The bracket won't be installed into studs, just that.

Also this document below shows 6 total holes in the bracket (3 each side) that are not countersink for screws, but it never explains what if anything is supposed to be inserted through those holes.

https://www.victronenergy.com/upload/documents/Quattro-48V-15000VA-230V.pdf

I'm guessing I need to find what goes into those six holes before trying to put this biggum up on the wall.

From this video, this guy seems to have only used those holes to attach the bracket to his cement board. Then he put his cement board up against his wall and used the screws to hold it up. It's too late for us to use those holes on cement board though, since that board is already up on the wall.

Last edited: