200 with a 200 main is 40A breaker or 32A continuous , 225 with 200 main is 70A breaker or 56A continuous

To be precise, solar isn't really rated as continuous and I don't think continuous is the right way to think about this.

Solar is separately given a 125% scaling factor (and it is 156% in some cases, but 125% for microinverter). So you can't say "my solar is not going to be at peak output because of reason X", you have to do 125% of AC nameplate UNLESS you have some approved way of limiting export via configuration.

I’m looking at Hoymiles, AP Power DS-3, or Enphase.

If I went with 29 Enphase IQ8M it’d look like: 29 x 1.35a = 39.15a So I could use a 40 amp breaker? Or am I missing something…..

Enphase has a bad reputation on this forum currently for poor AC coupling compatibility with hybrid inverter systems that don't also come from Enphase. And Enphase hybrid inverter/batteries kind of suck.

Enphase has a 20A branch circuit limit so you need two 20A 2 pole breakers and split the IQ8's accordingly

Hoymiles has a 30A branch circuit limit which gives more wiring flexibility.

I think Hoymiles might be slightly more DIY friendly, there are two distributors I know working with DIY. One of them (ncsolarelectric) is on this forum, and is who I bought my Hoymiles system from. Price out HMS1600-4T versus 4 IQ8Ms, the HMS1600 should be a fair chunk cheaper while also clipping less. Looking at the IQ8M, they can also clip due to 12A input current which is typically slightly under the STC output 54 cell panels (quite common these days), vs something 14A for HMS1600s which is squarely above the STC output of 54 cell panels.

You would need 7 HMS1600-4T and 1 HMS800-2T for your goal of hitting 30 panels.

IMO the main downside of Hoymiles vs Enphase is that it is unlikely for Enphase to disappear from US market, and it's much easier to buy Enphase accessories. There's also a good possibility that the handful of distributors for Hoymiles that do DIY will retire at some point. BUT if you save crap a ton of money up front, maybe you don't care about that.

Personally I think the bad IQ8 interoperability is a much worse problem.

You should investigate whether AP Power is actively anti-DIY.

Contrary to another post above, I don't think you need a separate combiner panel for all microinverters. For Enphase you should install one b/c you need one to hold some Enphase magic to comply with their standard installation.

For my Hoymiles install I used tandem breakers, but you can also achieve 40A with two single breakers at the bottom of your panel.

(i have these and like them a lot as they connect to 15A breakers in my electrical panel with 12-3 wiring).

Most microinverters these days are connected with L-L-G, rather than L-L-N-G.

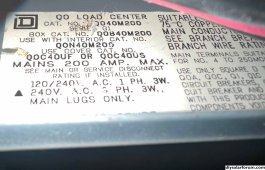

“QOM2FP- CLOSES 150-225 AMP. MAIN BREAKER OPENING.”

Much simpler if post a picture of the whole wiring label and we'll hunt for the busbar rating.

There's a QOM2175VH 175A breaker.