Yes, it surprised me to see that voltage on the battery, as I often touch my battery bus bars when it's all running and I'm still here!!Pretty wild having a 48V battery biased to some -150 or -200V with respect to earth.

Is it floating, just charged up? Would a high impedance pull it back to relatively safe voltages?

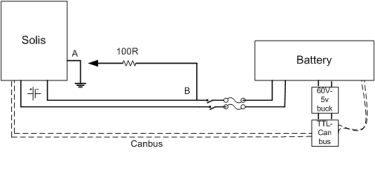

So, I suspected it is just floating and attempted to measure the current that would flow through a 100R resistor. All I got was a one off brief spark and zero current measurable through the resistor. But, in the process I managed to destroy another CANbus adapter, despite it not being attached to the Solis - puzzling as it is only connected to the battery -ve directly and the 5V +ve via the buck converter from battery +ve. I would have done more testing, but didn't want to zap anything else (including me!).

All a bit puzzling really - but maybe others who know more about the inverter's DC bus might chip in. @RCinFLA shared a nice diagram of how these inverters work (see https://diysolarforum.com/threads/t...ttery-and-inverter-to-mains.74684/post-946431). All that shows is a buck converter between the dc bus and the battery, so from that I'd deduce that whatever the 'ground' of the dc bus is using would get used for the -ve battery. Which sort of fits with it being at -195V, but if the DC Bus is floating wrt earth then I guess it doesn't matter.

No, I managed to zap an adapter without it connected on the comms side, so didn't feel there was any gain to check moreYou checked battery bias vs. ground, did you check logic/comms?

Yes, that makes sense. If I had more time (and spare components) I'd try putting my scope on it, just to understand it better... But the scope is grounded and Solar Guppy (who has a Solis) had previously said...If there is capacitance to a circuit, even though there is galvanic isolation, when common-mode is suddenly applied it forces in current. Which you may be able to measure, or measure voltage rise time and capacitance to determine current

ICs often spec not to drive inputs more than +/-0.4V relative to rails, but if they can have sufficient series resistance it protects them. Not so practical for fast outputs, but at remote inputs would limit current. Otherwise, when a device is unpowered the data lines can try to bring up its power rails through ESD protection diodes.

it is important that you do DO NOT GROUND PV or BATTERY +/- or you will permanently damage the unit