Alarchist

New Member

Guys, I'm having trouble with these ferrules. I'm starting to wonder if we should just put the wire in the breaker.

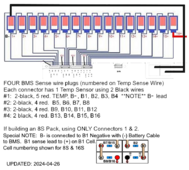

I'm using 2 AWG welding cable. Can someone please show me what you are doing?View attachment 211678

You don't need ferrules for that type of mechanical clamp terminal, It won't damage the strands unlike a direct screw 'choc block', if anything you'll minimise any increased resistance risk from possible poorly crimped ferrule, and get a better contact surface area than a thick uncompressible hard ferrule, only the super thin copper ferrules can be clamped securely at these larger gauge sizes if you really want to use them.

Last edited: