Steve_S

Offgrid Cabineer, N.E. Ontario, Canada

This is being changed from another Posting to THIS Thread.

Some slightly more detail will be added to the 1st-3 posts are reserved for that.

This is not for Argument, Debate & the usual Petty Nattering/Bickering, Thank You.

JUST the FACTS !

Luyuan Technologies is a Privately Family Owned & Operated Vendor.

Simple Intro:

This evolved from Amy Wan having experienced working with "Less Desirable Vendors" who were not very good and abusing buyers.

I couraged her to move forward & develop Luyuan to "Her Standards" because she always dealt with us Honourably & Respectfully even when working for "those" others. It was a Massive Challenge and I advised them on how to best start & keep a High-Level operation offering the best for everyone that dealt with them.

To be perfectly Blunt. I did all of this for them & others for Absolutely No Compensation or Reward Whatsoever!

This is also exemplified through the vast Majority of my Thousands of Posts on this Forum! All Old Timers KNOW THIS ! or Look.

WHY ?. Because I was Diagnosed with Terminal with Cancer in 2014, Given 5-7 yrs at Best, and am now in my Final Months - will not see 2023, so I got 1 Bonus (as such) year. I have ALWAYS been a Shareware, Freeway & OpenSource guy, and will be till I am planted Solid.

Luyuan Tech :

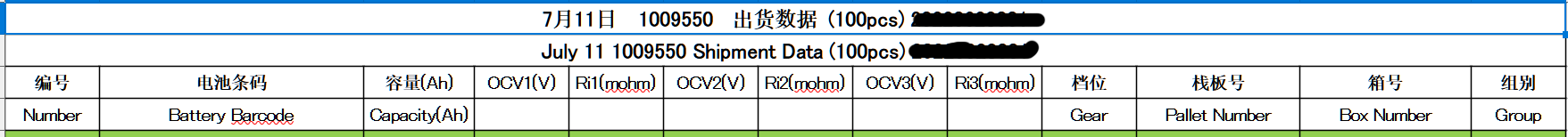

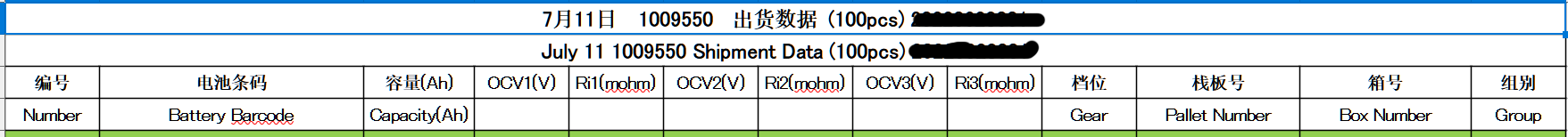

Matched & Batched A Cells are FACTORY tested @ EVE as runs through the batches produced.

This is the TEST Report received From EVE with the full data, Translated to English where necessary for your convenience.

"OCV1" refers to the voltage of the cell (unit: V), which is the initial voltage of the cell tested by the OCV tester after eliminating the "polarization" of the finished cell;

"R1" refers to the resistance of the cell (unit: mΩ), which is the internal resistance (AC internal resistance) tested by the OCV tester after eliminating the "polarization" of the finished cell;

OCV3" refers to the voltage of the cell (unit: V), which is the initial voltage of the cell tested by the OCV tester after the finished cell sits some time at room temperature;

"R3" refers to the resistance of the cell (unit: mΩ), which is the internal resistance (AC internal resistance) tested by the OCV tester after the finished cell sits some time at room temperature

www.alibaba.com

www.alibaba.com

Below are how the B-ESS Grade Cells are shipped without Reports.

NOTE: Screws / Bussbars.

FYI: Luyuan was the FIRST VENDOR to offer:

- such public Factory Reports and purchases ONLY from EVE, no brokers or middlemen. reports,

- the Enhanced Packaging for cells to reduce Damage during shipping & YES it is slightly more costly that the OLD 4 Cells per box.

- Was the FIRST to Offer Busbars, Screws (Even doubled up for DIYSolfar Forum Customers when stated where they came from)

- Published & Included the https://diysolarforum.com/resources/luyuan-tech-basic-lifepo4-guide.151/ which is included with the Cells.

YES I wrote that for HERE AND gave that to Luyuan to include + to Promo DIYS. For No COMPENSATION ! of any kind (Like BMS Manuals for Chargery Co, and Others, ALL for FREE... WHY Because I am NOW 6-8 months from DYING cancer... So DO NOT Argue with it!

Hope it Helps & Clarifies and I do not care What others have copied from Luyuan.

They are Still one of the Most Honourable you will find out there, Period.

FYI: Luyuan was the FIRST VENDOR to offer:

- making such public Factory Reports and purchases ONLY from EVE, no brokers or middlemen. reports,

- the Enhanced Packaging for cells to reduce Damage during shipping & YES it is slightly more costly than the OLD 4 Cells per box.

- Was the FIRST to Offer Busbars, and Screws (Even doubled up for DIYSolfar Forum Customers when stated where they came from)

- Published & Included the https://diysolarforum.com/resources/luyuan-tech-basic-lifepo4-guide.151/ which is included with the Cells.

YES I wrote that for HERE AND gave that to Luyuan to include + to Promo DIYS. For No COMPENSATION ! of any kind (Like BMS Manuals for Chargery Co, and Others, ALL for FREE)

Hope it Helps & Clarifies

I do not care What others have copied from Luyuan.

They are Still one of the Most Honourable you will find out there, Period.

Steve.

Some slightly more detail will be added to the 1st-3 posts are reserved for that.

This is not for Argument, Debate & the usual Petty Nattering/Bickering, Thank You.

JUST the FACTS !

Luyuan Technologies is a Privately Family Owned & Operated Vendor.

Simple Intro:

This evolved from Amy Wan having experienced working with "Less Desirable Vendors" who were not very good and abusing buyers.

I couraged her to move forward & develop Luyuan to "Her Standards" because she always dealt with us Honourably & Respectfully even when working for "those" others. It was a Massive Challenge and I advised them on how to best start & keep a High-Level operation offering the best for everyone that dealt with them.

To be perfectly Blunt. I did all of this for them & others for Absolutely No Compensation or Reward Whatsoever!

This is also exemplified through the vast Majority of my Thousands of Posts on this Forum! All Old Timers KNOW THIS ! or Look.

WHY ?. Because I was Diagnosed with Terminal with Cancer in 2014, Given 5-7 yrs at Best, and am now in my Final Months - will not see 2023, so I got 1 Bonus (as such) year. I have ALWAYS been a Shareware, Freeway & OpenSource guy, and will be till I am planted Solid.

Luyuan Tech :

Matched & Batched A Cells are FACTORY tested @ EVE as runs through the batches produced.

This is the TEST Report received From EVE with the full data, Translated to English where necessary for your convenience.

"OCV1" refers to the voltage of the cell (unit: V), which is the initial voltage of the cell tested by the OCV tester after eliminating the "polarization" of the finished cell;

"R1" refers to the resistance of the cell (unit: mΩ), which is the internal resistance (AC internal resistance) tested by the OCV tester after eliminating the "polarization" of the finished cell;

OCV3" refers to the voltage of the cell (unit: V), which is the initial voltage of the cell tested by the OCV tester after the finished cell sits some time at room temperature;

"R3" refers to the resistance of the cell (unit: mΩ), which is the internal resistance (AC internal resistance) tested by the OCV tester after the finished cell sits some time at room temperature

Amy2022-07-20 06:33

After we place an order with EVE, EVE will test and match the cells and then send them to us, also with the original test data of each cell.

Then,we will download the data to our own system. When we scan the QR code of each customer, the system will automatically generate a query link.

We will send this link to the customer.

Link for CURRENT Grade-A Level:For grade A, EVE tests&matches the cells, and they just tell us the test results, no how to test&match them.

For grade B (bulk cell), the test capacity is an option. It requires extra fees. If a customer needs that,we will test the cells

Eve Fully Matched Genuine Grade A 3.2v 280ah Lifepo4 (lfp) Cells Battery With 6000cycles Large Terminals Luyuan - Buy Solar System 389a Button Cell Battery 280v Lifepo4 Battery Product on Alibaba.com

Eve Fully Matched Genuine Grade A 3.2v 280ah Lifepo4 (lfp) Cells Battery With 6000cycles Large Terminals Luyuan - Buy Solar System 389a Button Cell Battery 280v Lifepo4 Battery Product on Alibaba.com

Below are how the B-ESS Grade Cells are shipped without Reports.

NOTE: Screws / Bussbars.

FYI: Luyuan was the FIRST VENDOR to offer:

- such public Factory Reports and purchases ONLY from EVE, no brokers or middlemen. reports,

- the Enhanced Packaging for cells to reduce Damage during shipping & YES it is slightly more costly that the OLD 4 Cells per box.

- Was the FIRST to Offer Busbars, Screws (Even doubled up for DIYSolfar Forum Customers when stated where they came from)

- Published & Included the https://diysolarforum.com/resources/luyuan-tech-basic-lifepo4-guide.151/ which is included with the Cells.

YES I wrote that for HERE AND gave that to Luyuan to include + to Promo DIYS. For No COMPENSATION ! of any kind (Like BMS Manuals for Chargery Co, and Others, ALL for FREE... WHY Because I am NOW 6-8 months from DYING cancer... So DO NOT Argue with it!

Hope it Helps & Clarifies and I do not care What others have copied from Luyuan.

They are Still one of the Most Honourable you will find out there, Period.

FYI: Luyuan was the FIRST VENDOR to offer:

- making such public Factory Reports and purchases ONLY from EVE, no brokers or middlemen. reports,

- the Enhanced Packaging for cells to reduce Damage during shipping & YES it is slightly more costly than the OLD 4 Cells per box.

- Was the FIRST to Offer Busbars, and Screws (Even doubled up for DIYSolfar Forum Customers when stated where they came from)

- Published & Included the https://diysolarforum.com/resources/luyuan-tech-basic-lifepo4-guide.151/ which is included with the Cells.

YES I wrote that for HERE AND gave that to Luyuan to include + to Promo DIYS. For No COMPENSATION ! of any kind (Like BMS Manuals for Chargery Co, and Others, ALL for FREE)

Hope it Helps & Clarifies

I do not care What others have copied from Luyuan.

They are Still one of the Most Honourable you will find out there, Period.

Steve.

Last edited: