OffGridInTheCity

Solar Wizard

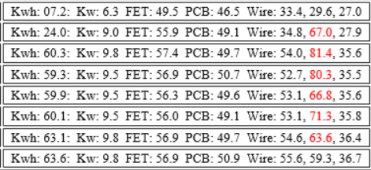

I'm just past 4 years of off-grid solar production and I had a serious issue and the fantastic Midnite support I got that helped me resolve the issue.

I use one of my Midnite Classic 150s AUX1 relay to turn on/off my inverters based on battery voltage. It started cycling every few minutes turning the inverters on/off - which cause all my ATSs to switch back and forth. It's not good for my system.

I went to the control room and all 3 Classics where blaring GND FAULT. So I like a good DIY'er I stuck my head in the sand and rebooted. Howerver, the one would not boot up - it just started to and then cycled over and over. I pulled out a spare and the same thing. I'm going to myself - did I just destroy 2 Midnite Classics?

Fired off a general tech support request and within 60minutes got back this:

---------------------------- email from Midnite ---------------------

From: Ryan [mailto:ryan@midnitesolar.com]

Sent: Wednesday, October 12, 2022 2:13 PM

To: Information; xxxx

Subject: Re: General Information - MidNite

Xxx,

You have a bad electrical connection some where between the battery and that classic. it is high resistance so when the classic tries to start it drops the voltage and resets

--------------------------------------------------------------------------

So I scratched my head and wondered how the 15ft wire from the Battery buss to the Midnite could possibly cause this. Bypassed the breaker and redid the lugs - no go. I took both Midnite Classics to my office and hooked them to a 48v battery - and they both booted properly!

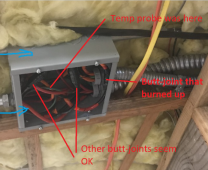

Then I remembered the original electrician put in a junction box and wa-la. He did butt-joints on 4AWG that carry up to 80a and one of them burned thru. Here's a pic of the junction box from Feb 2020....

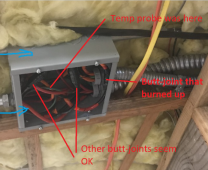

And here's the butt-join that burned up last week (Oct 2022)

Midnite tech support was 100% correct - bad connection between the battery and the Classic!

Connection is fixed and the Midnite Classic 150 is back onlineas good as ever. Also a good example of fire prevention gained by using metal junction boxes!

In these days of seemingly poor support, I just wanted to do a shout out to Ryan / Midnite Support!

I use one of my Midnite Classic 150s AUX1 relay to turn on/off my inverters based on battery voltage. It started cycling every few minutes turning the inverters on/off - which cause all my ATSs to switch back and forth. It's not good for my system.

I went to the control room and all 3 Classics where blaring GND FAULT. So I like a good DIY'er I stuck my head in the sand and rebooted. Howerver, the one would not boot up - it just started to and then cycled over and over. I pulled out a spare and the same thing. I'm going to myself - did I just destroy 2 Midnite Classics?

Fired off a general tech support request and within 60minutes got back this:

---------------------------- email from Midnite ---------------------

From: Ryan [mailto:ryan@midnitesolar.com]

Sent: Wednesday, October 12, 2022 2:13 PM

To: Information; xxxx

Subject: Re: General Information - MidNite

Xxx,

You have a bad electrical connection some where between the battery and that classic. it is high resistance so when the classic tries to start it drops the voltage and resets

--------------------------------------------------------------------------

So I scratched my head and wondered how the 15ft wire from the Battery buss to the Midnite could possibly cause this. Bypassed the breaker and redid the lugs - no go. I took both Midnite Classics to my office and hooked them to a 48v battery - and they both booted properly!

Then I remembered the original electrician put in a junction box and wa-la. He did butt-joints on 4AWG that carry up to 80a and one of them burned thru. Here's a pic of the junction box from Feb 2020....

And here's the butt-join that burned up last week (Oct 2022)

Midnite tech support was 100% correct - bad connection between the battery and the Classic!

Connection is fixed and the Midnite Classic 150 is back onlineas good as ever. Also a good example of fire prevention gained by using metal junction boxes!

In these days of seemingly poor support, I just wanted to do a shout out to Ryan / Midnite Support!

Last edited: