captainrivet

New Member

- Joined

- Jan 27, 2020

- Messages

- 73

Hi all,

What size of busbar do I really need for 600A in a 3P4S bank?

I have 99% Cooper tinned in 20mm x 5mm which I can double up or tripple (then I need to order more)

Depending on the source I get different rating for busbars, see below:

If I go with Victrons rating then i need 600/4,17 =143sqmm

20mm x 5mm= 100sqm = 417A, so if I double them up I get 20mmx10mm = 200sqmm means 834A

If I look for specs I find the following:

www.australwright.com.au

This source tells me: 1sqmm is 2,925A

www.australwright.com.au

This source tells me: 1sqmm is 2,925A

20mm x 10mm or 200sqmm is 585A,

25mm x 10mm or 250sqmm is 695A

If I go to an amperage calculator it tells me:

www.electrical4u.net

Putting into calculator: 1sqmm is 1.2A

www.electrical4u.net

Putting into calculator: 1sqmm is 1.2A

20 mm x 10mm or 200sqmm =240A

35mm x 15mm or 475sqmm =630A

20mm x 2mm =48A or 32a Alu (factory delivered busbars), really ???, Will Prowse pulled 1C= 272A when testing the cells with these busbars

Victron Lynx 1000 is rated for 1000A cont and has

a 30mm x 8mm= 240sqmm = 1000A (Cooper tinned busbar)

Victron rates 1sqmm= 4,17A

The flexible busbars by Webertech with 600A rating are

25mm x5mm = 125sqm = 600A

Webertech rates 1sqmm= 4,8A

www.aliexpress.com

www.aliexpress.com

I am building a 3P4S 816AH bank with 12x Lishen 272AH. I or most likely the wife will occasionally pull around 450A kinda continue during cooking (3 burner stove plus convection oven) for around 10-15min, normal average cooking operation is more like 150-250A.

To have some headroom and keep everything as cool as possible I like to spec for 600A. Please no discussion and upgrade to 24V, I have my reasons to stay 12V and the „extreme use“ is seldom but I need to spec for this plus some headroom to be safe.

What size of busbar do I really need for 600A in a 3P4S bank?

I have 99% Cooper tinned in 20mm x 5mm which I can double up or tripple (then I need to order more)

Depending on the source I get different rating for busbars, see below:

If I go with Victrons rating then i need 600/4,17 =143sqmm

20mm x 5mm= 100sqm = 417A, so if I double them up I get 20mmx10mm = 200sqmm means 834A

If I look for specs I find the following:

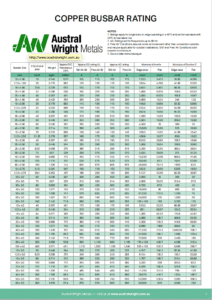

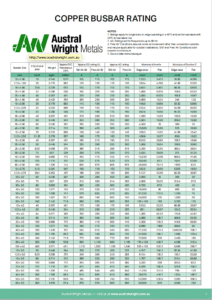

Copper Busbar Rating

View Copper Busbar Rating - Approx D.C rating (1). Approx A.C rating. Moment of Inertia. Modulus of Section Z. By Austral Wright Metals.

www.australwright.com.au

www.australwright.com.au

20mm x 10mm or 200sqmm is 585A,

25mm x 10mm or 250sqmm is 695A

If I go to an amperage calculator it tells me:

Busbar Current Calculator Online | Electrical4u

Enter the breadth and thickness of the busbar; do not enter the length of the busbar. Then press the calculate button, you get the aluminium or copper busbar

www.electrical4u.net

www.electrical4u.net

20 mm x 10mm or 200sqmm =240A

35mm x 15mm or 475sqmm =630A

20mm x 2mm =48A or 32a Alu (factory delivered busbars), really ???, Will Prowse pulled 1C= 272A when testing the cells with these busbars

Victron Lynx 1000 is rated for 1000A cont and has

a 30mm x 8mm= 240sqmm = 1000A (Cooper tinned busbar)

Victron rates 1sqmm= 4,17A

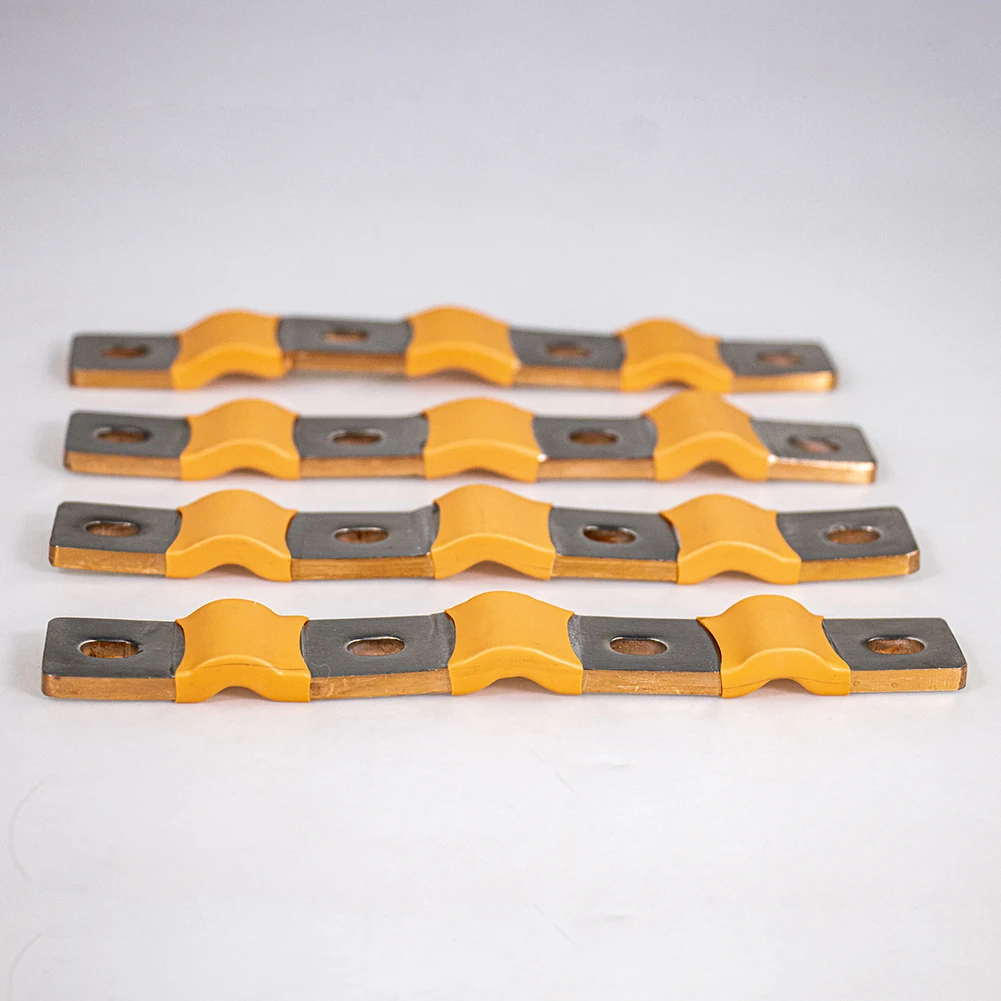

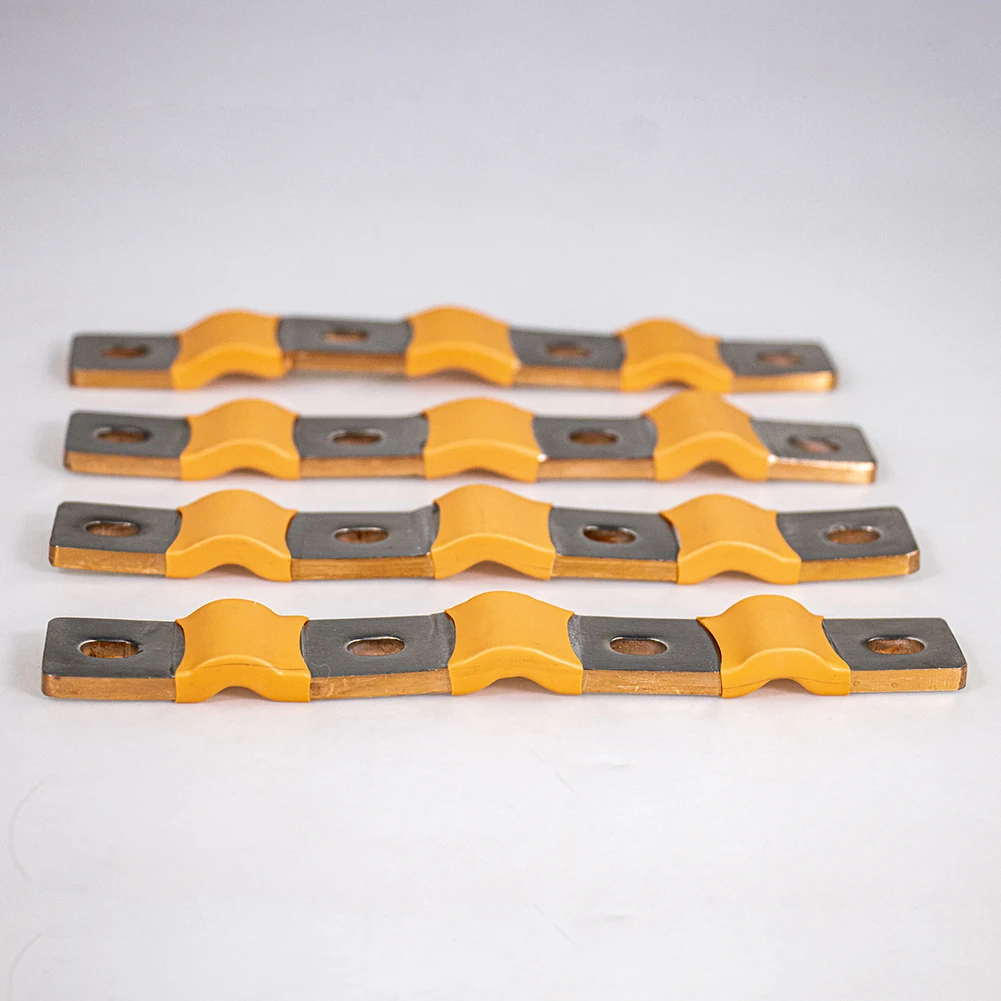

The flexible busbars by Webertech with 600A rating are

25mm x5mm = 125sqm = 600A

Webertech rates 1sqmm= 4,8A

10.68US $ 2% OFF|Flexible Busbars 17525b5 600a 500a 400a 300a - Rechargeable Batteries - AliExpress

Smarter Shopping, Better Living! Aliexpress.com

I am building a 3P4S 816AH bank with 12x Lishen 272AH. I or most likely the wife will occasionally pull around 450A kinda continue during cooking (3 burner stove plus convection oven) for around 10-15min, normal average cooking operation is more like 150-250A.

To have some headroom and keep everything as cool as possible I like to spec for 600A. Please no discussion and upgrade to 24V, I have my reasons to stay 12V and the „extreme use“ is seldom but I need to spec for this plus some headroom to be safe.