Hogheavenfarm

Regulation Stifles Innovation

- Joined

- Jun 24, 2022

- Messages

- 438

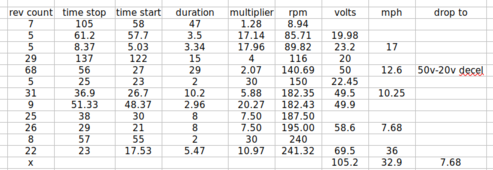

yes, did that early on, pretty similar to my later results but only had a DMM then, had to try to estimate the rpm by counting the times the blue stripe passed me while I was looking at the clock. Not very accurate. The graph used RPM calculated from movies taken of it while monitoring dmm and windspeed indicator, frame by frame count of the revs. Accurate, but not all readings available on every instance. Thats why the mph on the chart has a sag while the rpms are increasing, no reading of windspeed at that time.