RoadTurtle

Solar Enthusiast

- Joined

- Mar 30, 2022

- Messages

- 368

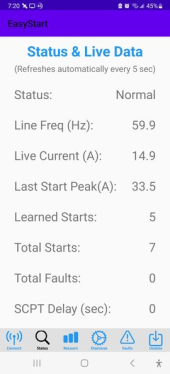

For my TT running on a 2500w generator, i installed microair easystart. aircon went from stalling the generator to running fine. .

Got a bit more interesting in the 5th wheel Multiplus II 2x. It would start the aircon, but MP went into overload, and I was scrambling to shut off anything 120v I could quickly grab. It started and ran, but it wasn't pretty. . Wow, what a difference, and now I have some data 15k ducted aircon. Without easy start, it and what I couldn't turn off, over 3k watts. Adding easy start, and same shut off loads I had before. .

15k ducted aircon. Without easy start, it and what I couldn't turn off, over 3k watts. Adding easy start, and same shut off loads I had before. .

I don't recall the exact numbers, but

400w when fan started up

800w after a few moment

1200w after a few more moments

1400w after a few more moment

1468w compressor finally kicks in .

Total time roughly 2+ minutes from system start to fully operational .

Installation took about 45 minutes. I could probably do one tomorrow in 15 minutes. Positive point, I found the hot copper line rubbing against the frame and it would probably have failed in a matter of months or a couple of years.

Got a bit more interesting in the 5th wheel Multiplus II 2x. It would start the aircon, but MP went into overload, and I was scrambling to shut off anything 120v I could quickly grab. It started and ran, but it wasn't pretty. . Wow, what a difference, and now I have some data

I don't recall the exact numbers, but

400w when fan started up

800w after a few moment

1200w after a few more moments

1400w after a few more moment

1468w compressor finally kicks in .

Total time roughly 2+ minutes from system start to fully operational .

Installation took about 45 minutes. I could probably do one tomorrow in 15 minutes. Positive point, I found the hot copper line rubbing against the frame and it would probably have failed in a matter of months or a couple of years.