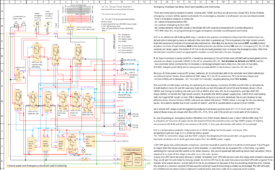

The 18k was not available 18 month ago. I hope I will not regret to choose the EG4-6500EX because it's sunset now. But they are working great so far and it was (at this time) an unbeatable price for a 6,500W inverter, 6,500W AC charger and 8,000W PV with 500Voc and two MPPT's. I would have loved to use Victron components (I'm using them in my RV) but it would have been much more expensive.

All AIO's are running at the latest firmware (DSP=79.71 and MCU=61.13) since it's available. The flickering in the early test phase also occurred with the newest firmware versions. Maybe as

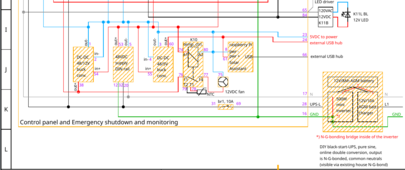

@wpns mentioned, it's because the base load is now a bit higher (the 9,000BTU minis split is now always running). Btw. Because the city required to install a 2-pole transfer switch (they didn't allow a previous planned 3-pole TS), I'm running with common neutral setup (program 42 set to ENA to disable the internal N-G-bonding relays) and the bonding screws are inserted in all six AIO's.

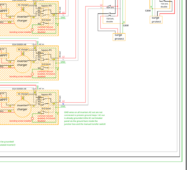

The AIO's are sucking cold air on the top side entries and blow the hot air out on the bottom and bottom side outlets - which is silly engineered because it would create a thermal shortcut. The hot air is rising and get sucked in at the top to cool the device - with this nonsense the AIO's are heating up very fast - whatever they smoked while they engineered the cooling system, they should smoke less of it

That's the reason why I've 3D printed these 45° windshields which are installed between each AIO and on the outer ones so the hot air will at least be separated a bit from the cold air.

Here are some more pictures in detail:

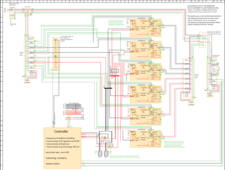

These small grey rectangle boxes (over the pos. busbar and below the wireway) are the two 600A/80VDC relays to disconnect each server rack from the positive busbar in case of an emergency.

View attachment 211115

View attachment 211127

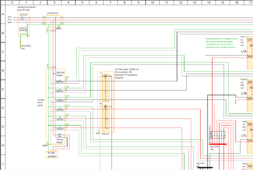

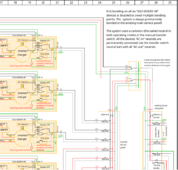

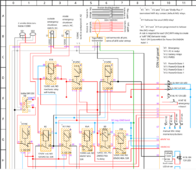

Here are the AC-out and AC-in combiner panels with surge protectors below both of them. The left metal box contains the 8 double pole PV breakers. The right plastic box contains the two 3-pole contactors to connect the grid with the AC-in's of the AIO's - but only if really required. I found out that if the AIO's are permanently connected to the grid, each unit will draw about 50W from the grid, even if grid is not used! In my case this would have been 300W permanently drawn from the grid, just to be prepared to use it - I don't want this! Maybe I need 5-10 days per year some hours gird support and I don't want to waste more than 2,600kWh per year. Instead I've implemented a smart home rule which only closes the AC-in contactors if required and before I initiate the AIO's program 12 "point back to utility" by adjusting this setting. After I will have enough solar again, I will initiate program 13 "point back to battery" by adjusting the voltage value via a smart home rule. While system is on grid, I've reduced the battery charging to the lowest possible value (2A per unit) because I don't want to charge the batteries from the grid.

View attachment 211119

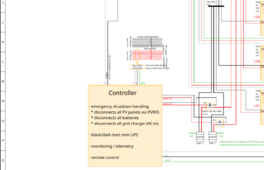

This picture shows the controller which implements the blackstart, the emergency control and the monitoring via SolarAssistant (via MQTT bridge to the existing smart home). Above the controller are the three components for the online-double-conversion-UPS (small inverter, small battery, small battery charger). This UPS has enough power to drive the controller with it's relays/contactors etc.\

View attachment 211124

View attachment 211125

View attachment 211126

The following picture shows the outside wall with the Tigo RSS transmitter with the two emergency shutdown buttons (the left will disconnect the PV modules, the batteries and the AC-in) and the right button just the PV modules via Tigo but the inverters will still running from batteries). Left of the main service panel is the transfer switch. The completely oversized box above the main service panel is just a box to splice the grid to the AC-in breaker panel and the transfer switch (this box and the transfer switch were the only parts which I've not installed by myself, it was done by an electrician).

View attachment 211131

View attachment 211133

View attachment 211134