Who said anything about shading?

Nobody, at least not directly.

But tracking (adjustable tilting) of panels is the topic, and area of land was brought up.

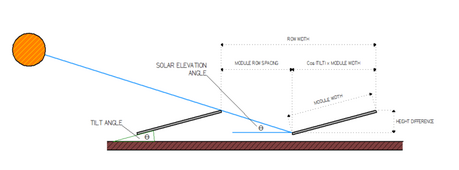

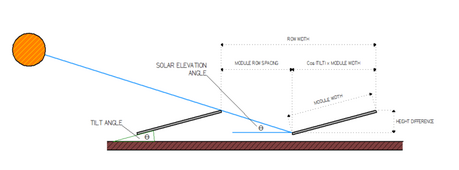

Any array, fixed or tracking, that has multiple rows of tilted panels has to be designed with consideration of shading.

When panels were 20 times more expensive, it could make sense to tilt the panels so they present more area toward the sun all day, rather than being hit at an oblique angle much of the time.

Tilted, in the morning and afternoon, they cast a long shadow. If too close, each row shades the next. To avoid that rows are spaced further apart, could be land area is 2x or more compared to panel area.

If panels are cheap enough, you could completely cover the land. When sun is at an angle such that tracker panels cast a shadow up to but not onto next row of panels, the area presented to sun by tracker would equal large flat array. When panels are horizontal, tracker would present same area to sun as before, less than the flat array would.

Placing panels in rows of inverted "V" spaced apart would be a compromise, fewer panels than covering entire land area, same production as tracker but without complexity.