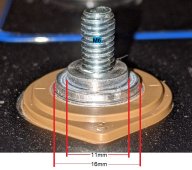

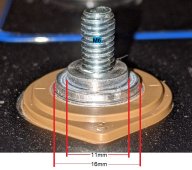

Just received 64 EVE 304AH cells and welded to the positive and negative terminals are M6 posts/studs on an 11mm base. (see images below)

The issue I'm concerned about is that the base is only a few mm thick at best and placing the busbar provided for interconnects over top of it doesn't give me much comfort that there's enough contact surface to adequately transfer and sustain up to 300 amps of current from the terminal through the post and across the bus bars back to the next terminal.

What could be done to help ease my concerns or should I be OK with this?

The issue I'm concerned about is that the base is only a few mm thick at best and placing the busbar provided for interconnects over top of it doesn't give me much comfort that there's enough contact surface to adequately transfer and sustain up to 300 amps of current from the terminal through the post and across the bus bars back to the next terminal.

What could be done to help ease my concerns or should I be OK with this?