callmeburton

New Member

- Joined

- Mar 4, 2022

- Messages

- 265

The only thing this problem is preventing me from doing is buttoning up the system ... so the covers are off for now. It "runs" it just doesn't run like I want it to (that is with the SMA not throwing errors in its logs) ...I know it doesn’t help right now but I’m hoping within the next week or so I should have my system ready for testing. I have a canbus (https://canable.io/) to usb so I can probably see if I get similar results or at the very least run a CAN dump.

We have had one light flicker event, but I didn't witness it so I can't confirm if it was true or not, from the SMA being odd (even though the batrium now controls the remote relay (SMA SI Bat OUT > Batrium Relay > Remote trip circuit I created)

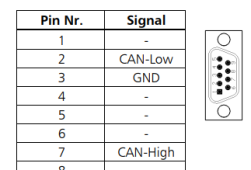

The only thing I can think of is that the CANBUS on the SMA SI requires the 120ohm resistor and pins 4/5/2 ... my IXXAT Usb-to-can does reference this is possible in the documents I have read but I don't have another setup on the side to test if this is true. I previously went through other pins for my electric motorcycle BMS / Controller to do the programming so I have never used those pins on my IXXAT before.

That said, the SMA SI will not run without a proper connection and input from the Batrium's Rj45 ... so it is "working" and at the same time not "working"

So yeah, all that to say having your setup doing a can dump in a week is very helpful as you might run into the same problem I am with the pins or you might not. And theoretically I got your same setup it should "work" for me to see what is going on. But right now, I can't get anything but a connection ... no Rx or Tx data on the computer side of things.