svetz

Works in theory! Practice? That's something else

Selecting the proper wire gauge can be tricky. In the US, the National Electrode Code (NEC) specifies the rules around wiring including gauge, grounding, and even color.

For the most part when you need wire for inside or to be buried underground you'll figure out the distance and number of amps it needs to carry. Then use a calculator or google a wire gauge table to get the minimum gauge for the ampacity; be sure to use the correct one (AC or DC) for your application (DC conductors may be twisted to minimize RF). When you go into a store like HomeDepot you'll look for the wire that meets your needs by having the proper gauge, if it can be buried, the proper number of conductors, if it's waterproof, gasoline resistant, etc.

Cables, or cables in conduits, that are exposed to sunlight (e.g., on your roof) or heat are subject to special rules that may change the gauge or require the wire be elevated off the roof. Since Solar installations almost always have this element it's important to understand these. This video will help you understand how to use the tables below, and you can then refer back to this post as a reference guide.

Types of Cable

Alternating Current (AC) and Direct Current (DC) are conducted across one or more copper wires embedded in a sheath called a cable. The wire can be solid or stranded. Stranded is more flexible and easier to pull through conduits and bend, but it is harder to manufacture and more expensive.

Gauge refers to the thickness of the wire, the lower the number the thicker the wire. In general, thicker wires can carry more current without heating than than thin ones. Calculators are use to find the gauge of a wire for a voltage drop for a specified distance; be sure to use one designed for AC or DC currents as they may give a different gauge for a specific voltage loss. Some common types of cables used in solar projects are:

USE-2: UV resistant, can be used in wet or dry, okay to be buried, cannot be in conduit (unless marked RHW-2 and/or XHHW-2). Typically used from modules to combiner box.

PV Wire: Similar to USE-2, available up to 2kV, required for ungrounded systems (transformerless).

THWN-2/XHHW-2: Used in wet or dry, NOT resistant to UV, must be in conduit. Typically used form combiner box to DC Load center

THW: Dry locations only, usually battery cables

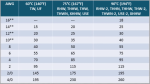

On the left is NEC table 310.15(B)(16) which provides the allowable ampacity at 30C, if the wire type isn't listed use the wire's temperature rating to select the correct column.

Example: 8 AWG RWG has a maximum ampacity of 50 amps.

Useful links

Over 30C Applications: Wires & Conduits exposed to the Sun

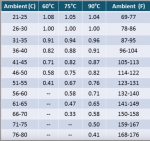

Above on the right is NEC table 310.15(B)(2)(a); it covers the temperature correction factor for over 30C.

Example: The correction for 75C wire at an ambient temperature of 42C is 0.82, So RHW 8 AWG at an ambient of 42C has an ampacity of .82X50=41 amps

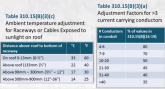

The next two NEC tables are adjustments for heat with the conduit off the roof. The closer the conduit is to the roof, the hotter the wires are. The more conductors in the conduit the more heat they dissipate. If there are less than 4 wires in the conduit you do not need to adjust using 310.15(B)(3)(a).

From Table 310.15(B)(3)(c) you add the temperature correct factor to the ambient temp

Max Circuit Current = Isc x 1.25 (over-irradiance)

Continuous Current = Max Circuit Current * 1.25

If a breaker has a lower temperature rating than the wire rating, then the breaker temperature must be used

Wiring that is shaded or not in conduit does not require conduit fill adjustments.

To calculate the gauge you take the Continuous current and then modify the factors. For example if the Continuous current is 14.2 amps for a wire in the shade (e.g., under panels) that has a 75C breaker when the ambient temperature is 37C you'd divide by .88, so 14.2/.88 = 16.1 Amps. You can then go to 310.15(B)(16) and using the 75C column learn that 14 AWG is the smallest possible wire that can handle the amperage.

If any of that doesn't make sense please watch the video again.

For the most part when you need wire for inside or to be buried underground you'll figure out the distance and number of amps it needs to carry. Then use a calculator or google a wire gauge table to get the minimum gauge for the ampacity; be sure to use the correct one (AC or DC) for your application (DC conductors may be twisted to minimize RF). When you go into a store like HomeDepot you'll look for the wire that meets your needs by having the proper gauge, if it can be buried, the proper number of conductors, if it's waterproof, gasoline resistant, etc.

THHN/THWN letters represent the most common types of individual wires used in residential applications.

|

Types of Cable

Alternating Current (AC) and Direct Current (DC) are conducted across one or more copper wires embedded in a sheath called a cable. The wire can be solid or stranded. Stranded is more flexible and easier to pull through conduits and bend, but it is harder to manufacture and more expensive.

Gauge refers to the thickness of the wire, the lower the number the thicker the wire. In general, thicker wires can carry more current without heating than than thin ones. Calculators are use to find the gauge of a wire for a voltage drop for a specified distance; be sure to use one designed for AC or DC currents as they may give a different gauge for a specific voltage loss. Some common types of cables used in solar projects are:

USE-2: UV resistant, can be used in wet or dry, okay to be buried, cannot be in conduit (unless marked RHW-2 and/or XHHW-2). Typically used from modules to combiner box.

PV Wire: Similar to USE-2, available up to 2kV, required for ungrounded systems (transformerless).

THWN-2/XHHW-2: Used in wet or dry, NOT resistant to UV, must be in conduit. Typically used form combiner box to DC Load center

THW: Dry locations only, usually battery cables

On the left is NEC table 310.15(B)(16) which provides the allowable ampacity at 30C, if the wire type isn't listed use the wire's temperature rating to select the correct column.

Example: 8 AWG RWG has a maximum ampacity of 50 amps.

Useful links

- Example calculations for when wiring panels long distances (e.g., 100') to the house

- Other types of Commonly used cables

- Wire Bending Radius

Over 30C Applications: Wires & Conduits exposed to the Sun

Above on the right is NEC table 310.15(B)(2)(a); it covers the temperature correction factor for over 30C.

Example: The correction for 75C wire at an ambient temperature of 42C is 0.82, So RHW 8 AWG at an ambient of 42C has an ampacity of .82X50=41 amps

The next two NEC tables are adjustments for heat with the conduit off the roof. The closer the conduit is to the roof, the hotter the wires are. The more conductors in the conduit the more heat they dissipate. If there are less than 4 wires in the conduit you do not need to adjust using 310.15(B)(3)(a).

From Table 310.15(B)(3)(c) you add the temperature correct factor to the ambient temp

Max Circuit Current = Isc x 1.25 (over-irradiance)

Continuous Current = Max Circuit Current * 1.25

If a breaker has a lower temperature rating than the wire rating, then the breaker temperature must be used

Wiring that is shaded or not in conduit does not require conduit fill adjustments.

To calculate the gauge you take the Continuous current and then modify the factors. For example if the Continuous current is 14.2 amps for a wire in the shade (e.g., under panels) that has a 75C breaker when the ambient temperature is 37C you'd divide by .88, so 14.2/.88 = 16.1 Amps. You can then go to 310.15(B)(16) and using the 75C column learn that 14 AWG is the smallest possible wire that can handle the amperage.

If any of that doesn't make sense please watch the video again.

Last edited: