I am trying to write this so you understand >>>> it is 8 cells connected in parallel first!!!! which acts as a single large cell and will be balanced by one of the small sense wires from the Electrodacus SBMS0...

then each of those large paralleled cells will be interconnected to the next set of 8 parallel cells in series, then the next in series, then the next in series etc... with the final series connections yielding 25.6 volts nominal...

54 series cable interconnections

then 16 more connections via copper cable to the busbar on each end (8 on each end)

yes, it is confusing but it has worked well in the 2P8S and 4P8S builds.....

I will increase the cabling sizes and the busbar sizes....

the factory bus bars work well for the parallel connections...

the series interconnections I use tinned copper lugs with short copper cables that I make up with a hydraulic crimper and use adhesive heat shrink to cover these lugs....

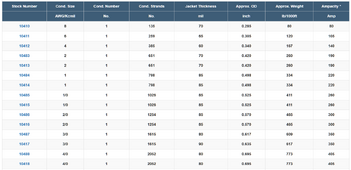

I may use 4/0 copper for the interconnections as I already have that cable and all the 4/0 lugs to fit....

it will take about 6 hours to make up those cables (approximately) (((((54 plus 16 is 70 cables to hydraulically crimp etc...)))))

64 cells at 5.4 kg weighs a lot >>>> 64x5.4 = 345.6 kg or (( for me 345 x 2.2 = 760.32 pounds)) Approximately not including the bus bars or cabling !!!!!!

the cells are connected in parallel 1st to make the 8P combined cell using 280Ah Eve Cells in this build..

64 cells will ultimately be an 8x8 block to make the 64 cell battery....

multiple inverters can be hooked to the same bus bars also,,,, and not the high overpriced Victron super dependable everyone raves about either....

I am still learning through many years of reading...//// studying.....DIY for 50 plus years farm boy for 60 plus years college 10 plus years.... still learning every day so suggestions are always read and studied before implementing....

but it still seems when one gets to adding up all the required charge controllers, pv combiner boxes, etc to control 18,000 watts of PV solar panels this still is doable a few parts at a time....

no combiner box is needed when assembling the 2 panels at a time in parallel at the solar PV array....

the LiFePO4 battery back-up is the most expensive part of my systems.... off-grid

I am not connected to the grid in any way on this....