Aridom82

Learning addict

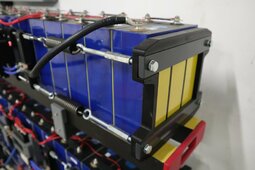

Following fellows forum members feedback i added some changes to my battery rack.

I changed the Bms holder to make use of the M3 threaded holes the Jk bms comes with, now it has more air circulating around it.

I added a mini bracket for the jkbms button on the right

I changed the connector brackets to help the current go equally to both wires in the Jk bms.

I added a bracket to the Dcbreaker holder to fix in place the T-fuse in case it pops so the wire does not come loose.

I will add all of these stl files to the resources so anybody can replicate or modify this project

I changed the Bms holder to make use of the M3 threaded holes the Jk bms comes with, now it has more air circulating around it.

I added a mini bracket for the jkbms button on the right

I changed the connector brackets to help the current go equally to both wires in the Jk bms.

I added a bracket to the Dcbreaker holder to fix in place the T-fuse in case it pops so the wire does not come loose.

I will add all of these stl files to the resources so anybody can replicate or modify this project