Point me to a thread on how to have the SA box interface to both the inverter and the battery bank. That sounds like a great setup.I want and need battery comms, that's why my BMS's talk to Solar Assistant.

I'm warming up to the idea the batteries comms can be not tied to the inverter but monitoring by SOMETHING seems important. If SA can do that, then that's a win.

Building your own battery bank from individual cells seems foolish these days. Even with free labor, you can't really achieve a better cost than what you can buy.For ~$4000 with shipping and BMS's you can get ~31kWh and build your own that are easily serviceable.

On balancing:Haha, lots. Mainly keeping the 12V packs in balance, not being able to service them and not being able to monitor cells.

The battery maker says 4 in series (48V V) is okay, and if they are slowly top charged, that should keep them in balance. When the lowest capacity battery BMS trips out, the entire series string goes away, which then means every battery in the string had the same AH usage at that moment. Then the can all recharge back to full with the same AH put back in. Still, I get the point and it is better not to put these things in series if you can avoid it.

On servicing:

I don't see any difference between a rack mount and the big brick style. A bad cell and the whole thing is busted. If you put in a replacement cell (which would be a chore for either type), it is of a different age, capacity, etc, so balancing will be off. The "servicing" of the batteries is replacing a unit entirely.

The rack mounts at 48V are better in this regard since they are full voltage and thus you don't break up a string.

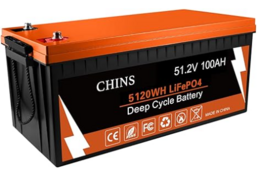

For both of the above concerns, there are 48V 100 AH versions:

$978, so similar in price. Now each one can balance all the cells in series internally. Another advantage is that you can size your system in 5 KWH chunks, not in 20 KWH chunks.

On monitoring:

Yes, they have no SA or other logging style interface, so you lose that. They do have BT with an app, and you can use that to check for faults and other issues, but it isn't an appropriate logging style interface like one that would work well with SA.

That's what matters.Regardless what we choose all that matters is we are happy with our system.

I'm very excited about what one can do with solar these days. A prime factor in that is how you can drive the cost down which is key to wider adoption, which also means lower costs for everybody.

Mike C.