Nobodybusiness

Solar Sponge.

I suppose you could do that.I think you mis-understood, im talking about getting 2 of the 4-1s because i cant find a 2-1s or 4-2s with everything plug and play and simple.

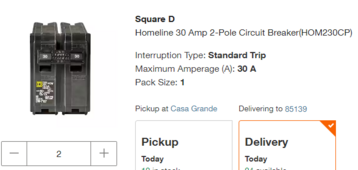

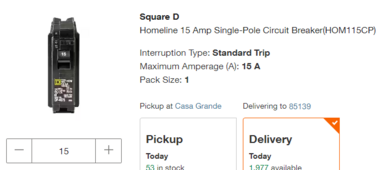

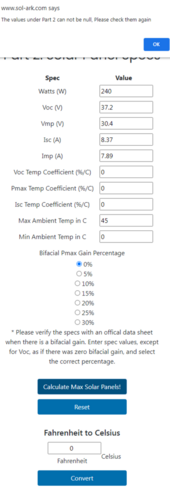

That would give me 8 total inputs, but i only intend to use 2 inputs on each one. And I know the fuses are built into the combiner, but some have 10A some are 15A, some are 20A, which one is right for this purpose if i use two of the 4-1s??

View attachment 209048

2 parallel strings would be 16 amps max.

Last edited: