Brucey

Solar Wizard

Value option for off the shelf still seems to remains with the ecoworthy 12V 280Ah for $1000 a pair, 14kWh for $2k (four in series). Nothing fancy, no comms, no BT, just raw capacity.

About $172/kwhr.So with my three purchases I have 72+kWh in ten 24v custom boxes for $12,448.00. Including four extra JK BMS, two screens, on/off switches and two extra breakers, 40 flexible buss bars plus 8 meters 2ga 200 degree silicone wire.

If you add an ecoworthy balancer for $55, this solution is about the same cost as 4- $170 100ah batteries plus a balancer.Value option for off the shelf still seems to remains with the ecoworthy 12V 280Ah for $1000 a pair, 14kWh for $2k (four in series). Nothing fancy, no comms, no BT, just raw capacity.

Damn you remind me of some of my friends... I bet if we went out for a weekend they would make a movie of our exploits... can you still collect money from royalties if you are in jail?I have a power line next to my house I’m building. I think it averages less than ~$0.15/kW when including fees and taxes.

So no way is it ever going to “pay off” for me going off-grid solar. But if I didn’t spend so much money on Solar, I’d have money for hookers and blow. And my priest told me I had to stop that, not a healthy hobby apparently.

glad to hear you are making some headway. I remember you saying before that the shipping considerations were causing you issues. hope you got them all sorted out............I just received 16 Batterotech 280Ah cells from GobelPower today......this is rather..........unexpected..........

Havent got the time to install it yet. Still very surprised with the delivery......

16 Kwh per day is 5840 Kwh per year.I assumed a ten year life with a battery and inverter cost of $11,000. I also assumed I would use 16 kWh per day on a 42 kWh pack. So $11,000 divided by 3650 days is a cost per day of $3 per day. Then $3 per day divided by 16 kWh is $0.20 per kWh. It is a little less than 1500 cycles. I am sure there are a few different ways to calculate long term cost of operation per kWh.

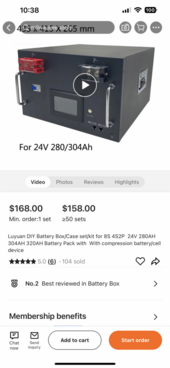

I'll have about $146 per Kwh in the Luyuan boxes with wheels with 200A JK BMS, large screen and adding a Class T fuse. Cells are 280Ah Grade A from Luyuan This includes freight.So with my three purchases I have 72+kWh in ten 24v custom boxes for $12,448.00. Including four extra JK BMS, two screens, on/off switches and two extra breakers, 40 flexible buss bars plus 8 meters 2ga 200 degree silicone wire.

No doubt, and if I were a utility scale facility I could bring that cost down significantly as you pointed out in another post.. But I don't have a practical way to do that until I install a HPWH and even that will be trivial. I already charge my EVs from excess solar at $0.05/kWh so that is not an option. Initially going with a smaller pack size would accomplish part of that but the inverter size would not scale down so there is diminished return with that approach and would leave me with no reserve in the event if a power outage. It is academic for me anyway because that cost is still lower than buying from my power company.Using your figures, if you double the usage, you halve the $ cost per Kwh.

That assumes they last 16.5 years of daily 0 - 100% cycling with zero degradation or 18.3 years down to 80% SOH. More likely you only get 1/2 a cycle per day and batteries last 10 years before other cell failure mode requires replacement (self discharge, internal resistance). In that case you get 1825 full equivalent cycles or $0.077/kWh. Still pretty good.$2044 divided by 84,000 = $0.0243 per Kwh over the lifespan if these last 6000 cycles.

Are they serviceable? What about when you have a cell go bad, are the buss bars welded?About $172/kwhr.

Honestly I think that should be available for $125/kwhr. After all I can buy a 12v 100 amp hr battery for $170 delivered. That works out to $136/kwhr. And those are cased with a bms. A slightly different animal, but not that much

Yep I got extra BMS and other extra parts, if I strip them out that is about another $500.00 less and the shipping. So under 12k.I'll have about $146 per Kwh in the Luyuan boxes with wheels with 200A JK BMS, large screen and adding a Class T fuse. Cells are 280Ah Grade A from Luyuan This includes freight.

6000 full cycles is 84,000 Kwh. Battery cost is $2044

$2044 divided by 84,000 = $0.0243 per Kwh over the lifespan if these last 6000 cycles. BMS might not last that long but those are fairly cheap.

What does battery cost ($2044) include, is that one 48v box complete?I'll have about $146 per Kwh in the Luyuan boxes with wheels with 200A JK BMS, large screen and adding a Class T fuse. Cells are 280Ah Grade A from Luyuan This includes freight.

6000 full cycles is 84,000 Kwh. Battery cost is $2044

$2044 divided by 84,000 = $0.0243 per Kwh over the lifespan if these last 6000 cycles. BMS might not last that long but those are fairly cheap.

Im not saying 12 v batteries are the best or cheapest solution, other things should be much cheaper, but they are very easy to use. Tied together with cables and a balancer. If one goes bad you remove it and replace with a new battery. From what I see everything else is more difficult to repair and get up and running again. Most packaged batteries have a 5 year warranty. Who knows how good that is until you need to use it.Are they serviceable? What about when you have a cell go bad, are the buss bars welded?

There is no way you can convince me they use grade A cells and the price I listed includes four extra cells and spare parts as well. I place value in quality of product, not just looking for the cheapest option.

View attachment 212023

View attachment 212022

That was complete cost for one 48V box complete. 16 cells, 200A JK BMS with screen (older version BMS without comms), 175A Class T fuse and holder. I'll have a couple of terminals used and a small amount of cable to build it the way I want.What does battery cost ($2044) include, is that one 48v box complete?

Or the cells last 25 years. We don't know at this point, calendar aging will most likely be the biggest detriment to battery longevity. My banks are fairly large and cycled lightly, never overworked. That could be a + or -.That assumes they last 16.5 years of daily 0 - 100% cycling with zero degradation or 18.3 years down to 80% SOH. More likely you only get 1/2 a cycle per day and batteries last 10 years before other cell failure mode requires replacement (self discharge, internal resistance). In that case you get 1825 full equivalent cycles or $0.077/kWh. Still pretty good.

The $2044 I quoted is with a Class T fuse. If I take that out, I have your ecoworthy beat and I have much better cells that are serviceable.Value option for off the shelf still seems to remains with the ecoworthy 12V 280Ah for $1000 a pair, 14kWh for $2k (four in series). Nothing fancy, no comms, no BT, just raw capacity.

Ok that makes sense, I’m a bit above that from the extra box kit, bms and screen going 24v. And my cells are 304’s.That was complete cost for one 48V box complete. 16 cells, 200A JK BMS with screen (older version BMS without comms), 175A Class T fuse and holder. I'll have a couple of terminals used and a small amount of cable to build it the way I want.

That is freight included.

Or the cells last 25 years. We don't know at this point, calendar aging will most likely be the biggest detriment to battery longevity. My banks are fairly large and cycled lightly, never overworked. That could be a + or -.

Time will give the answer.

I put in an order of 96 cells and two boxes. She gave me a good deal.Ok that makes sense, I’m a bit above that from the extra box kit, bms and screen going 24v.

I did my 84 cells and 12 boxes in three orders and had her include extra everything in the last order.I put in an order of 96 cells and two boxes. She gave me a good deal.

That said I'm having to open every box and count the plates, screws and busbars. I believe I'm short. Taking a break before the last 6 boxes. I know it's short and she will have to send more. This was all on a nice pallet and I wasn't planning on breaking it all down yet.

Yes, basically instead of a RAID (redundant array of independent disks) , we have a RAIB (redundant array of independent batteries). If a 12V battery fails, pull it out and throw another one in.Im not saying 12 v batteries are the best or cheapest solution, other things should be much cheaper, but they are very easy to use. Tied together with cables and a balancer. If one goes bad you remove it and replace with a new battery. From what I see everything else is more difficult to repair and get up and running again. Most packaged batteries have a 5 year warranty. Who knows how good that is until you need to use it.

If you have a rack that goes bad, is that user serviceable? Maybe not.