FilterGuy

Solar Engineering Consultant - EG4 and Consumers

Warning: I go full propeller head on this post!!! ?

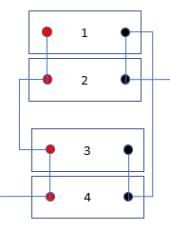

@Will Prowse just released a couple of videos about hooking parallel batteries together. One commenter claimed 4 batteries in parallel but hooked up 'Diaganaly' would stay balanced. 2 batteries in parallel with diagonal connections is balanced any more in parallel will be out of balance.

I decided to nerd out and try to model the diagonal battery hook-up. (I tried this once before but got wrapped around the axil... I tried a different approach this time and it worked out)

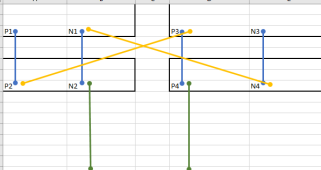

For simplicity, I only modeled 2 in parallel with diagonal connections and 3 in parallel with diagonal connections.

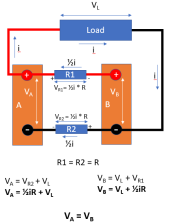

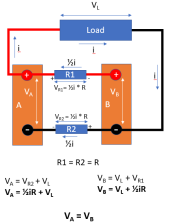

2 Batteries:

Assume the resistance of the interconnecting cables are all identical and of value R.

Since each battery is only carrying half the current, the cables between the two positive terminals will carry half the total current. Likewise, the current between the two negative terminals will carry 1/2 the current.

To calculate the voltage on battery A, start at the battery A negative terminal and add the voltages as you go around the loop.

Va = The voltage across R2 + Voltage across the load. The voltage across R2 = 1/2 I * R, so the voltage across battery A is VL + 1/2*I*R

Now calculate the voltage on battery B by starting at the Battery B negative terminal and adding the voltages around the loop..... it comes out to 1/2*i*R + V2

So.... the voltages on the two batteries are the same and therefore the load is the same and they are balanced.

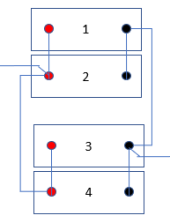

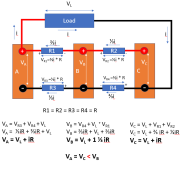

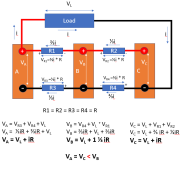

Now let's look at 3 batteries.

The big difference here is that the current on each of the interconnects is not the same

The positive linkage between Battery C and Battery B is 1/3 of the total current

The positive linkage between Battery B and Battery A is 2/3 of the total current.

Similarly, the interconnects on the negative are 1/3 and 2/3 of the total.

(This turns out to be a good first approximation. It is good enough to prove the point but not 100% accurate... more on this below)

Now when you go around the loop and calculate the voltages you get this:

Va = Vl + i*R

Vb = Vl + 1 1/3*I*R

Vc = Vl + I*R

As you can see, the voltage on battery B is slightly higher than on batteries A and C. This means it will be contributing less current. This is not a balanced arrangement. As you add more batteries, this pattern continues to get worse. The middle batteries will always be stressed less than the outer batteries.

Notice that since the voltages are not the same across all 3 batteries, the current contribution of B will be less than for A and C. This is why I said the 1/3 - 2/3 current model is only a first approximation. However, after doing a sensitivity analysis on the approximation, I concluded that it does not change the model in any significant way.

@Will Prowse just released a couple of videos about hooking parallel batteries together. One commenter claimed 4 batteries in parallel but hooked up 'Diaganaly' would stay balanced. 2 batteries in parallel with diagonal connections is balanced any more in parallel will be out of balance.

I decided to nerd out and try to model the diagonal battery hook-up. (I tried this once before but got wrapped around the axil... I tried a different approach this time and it worked out)

For simplicity, I only modeled 2 in parallel with diagonal connections and 3 in parallel with diagonal connections.

2 Batteries:

Assume the resistance of the interconnecting cables are all identical and of value R.

Since each battery is only carrying half the current, the cables between the two positive terminals will carry half the total current. Likewise, the current between the two negative terminals will carry 1/2 the current.

To calculate the voltage on battery A, start at the battery A negative terminal and add the voltages as you go around the loop.

Va = The voltage across R2 + Voltage across the load. The voltage across R2 = 1/2 I * R, so the voltage across battery A is VL + 1/2*I*R

Now calculate the voltage on battery B by starting at the Battery B negative terminal and adding the voltages around the loop..... it comes out to 1/2*i*R + V2

So.... the voltages on the two batteries are the same and therefore the load is the same and they are balanced.

Now let's look at 3 batteries.

The big difference here is that the current on each of the interconnects is not the same

The positive linkage between Battery C and Battery B is 1/3 of the total current

The positive linkage between Battery B and Battery A is 2/3 of the total current.

Similarly, the interconnects on the negative are 1/3 and 2/3 of the total.

(This turns out to be a good first approximation. It is good enough to prove the point but not 100% accurate... more on this below)

Now when you go around the loop and calculate the voltages you get this:

Va = Vl + i*R

Vb = Vl + 1 1/3*I*R

Vc = Vl + I*R

As you can see, the voltage on battery B is slightly higher than on batteries A and C. This means it will be contributing less current. This is not a balanced arrangement. As you add more batteries, this pattern continues to get worse. The middle batteries will always be stressed less than the outer batteries.

Notice that since the voltages are not the same across all 3 batteries, the current contribution of B will be less than for A and C. This is why I said the 1/3 - 2/3 current model is only a first approximation. However, after doing a sensitivity analysis on the approximation, I concluded that it does not change the model in any significant way.

Last edited: