I am ready to install my AC disconnect. It has to be accessible to POCO personnel, so to me, that means outside. Here is a photo of where I plan to put it. I chose that location for ease of installation and because the line side connections are on the top of the switch. Is that spot in violation of any clearance or other requirements?

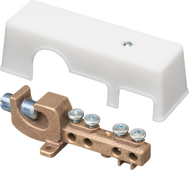

I also have a few wiring questions. L1 and L2 each have an available port on the multitap connector so I can use that. Neutral doesn't because that is where N-G is bonded.

I also have a few wiring questions. L1 and L2 each have an available port on the multitap connector so I can use that. Neutral doesn't because that is where N-G is bonded.

- Is it legal to put two wires in one port of the multitap on the neutral line? I know you can't do that with circuit breakers unless they are specifically designed that way. If not, I will buy a 5 port multitap. They ain't cheap - are there any other options?

- Can I use PVC conduit to run L1, L2, N and G from the disconnect along the outside wall to where it will go inside the house? Also, should I transition to RMC going through the brick wall? Another option would be to feed the load side wires back up into the raceway and go all the way to the right where it could enter the house through the back of the raceway. It would be a cleaner installation, if allowed.

- The line side of the disconnect will be fed with #4 wire since that is the minimum size allowed for that particular multitap. Is it okay to run #6 wire from the load side of the disconnect to the inverter (Inverter rated at 48 amps)