Would you run these batteries without a bms? What BMS would you choose?

FUCK NO!

Now, be honest... I actually did run a 24V system for a short period with no BMS; however, I capacity tested all cells, balanced all the cells to 4.05V, installed active balancers and kept the charge voltage to 27.4V (3.92V/cell - 75% SoC), and only ran it for a short while watching it like a hawk.

Would I do that again? Yes, but only for temporary/experimentation purposes.

I'm using Batrium. It's the most luscious headache I've ever had, and they charge a premium for the honor of causing me pain. If 100A is enough, I'd just go with a 7S JBD. You can probably find them in higher currents.

If you have the four modules (one pack), and they're all out of one car, and they are all sitting at ±.01V of each other, they are likely all the same capacity.

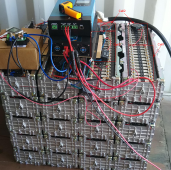

Before I continue, this test was purely for proof of concept AND it utilized only things I had on-hand, spare wire, ring terminals, bus bars, etc. It fails every "best practice" on the planet concerning building lithium batteries. I knew the risks, and I took precautions, I KNEW they were all the same capacity and internal resistance, and I can't tell you how many times I was out there measuring all 7 cells with a voltmeter just to make sure!

AND, this was about making it work fast with what I had on hand... not neat or pretty. It was in operation for maybe 4 days total.

For my initial test battery (I had 20 modules, used 4) I rearranged the cells in the modules in a 12P7S format. This required me to split each "cell" across packs.

Each NMC cell is around 20Ah if in decent shape. New is 25Ah.

CX = Cell 1, 2, 3, etc.

YP = # of NMC cells in parallel

Module 1: C1-12P, C2-9P

Module 2: C2-3P, C3-12P, C4-6P

Module 3: C4-6P, C5-12P, C6-3P

Module 4: C6-9P, C7-12P

I connected each module in series with 8awg superworm wire good for > 70A

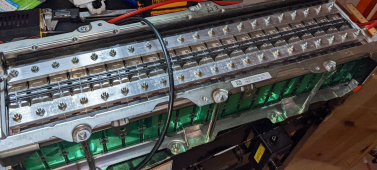

On the right side of the pack, I have drawn red lines indicating where the cell "breaks" are and circled the terminals where one crossover wire is evident.

The little black boxes are active balancers that are supposed to keep adjacent cell voltages within .02V of each other.

This would be an option for you if you want a larger, 240Ah battery with a single BMS rather than 4 smaller batteries, each with its own BMS.

I know I've said it before, but I'll say it again, if I had to do it all over, I would have gone with LFP. It would have cost the same as 7 Energi packs, and I would have been done two years ago.