boondox

Chief Engineer, RedNeckTech Industries

- Joined

- Mar 1, 2020

- Messages

- 788

Hi All,

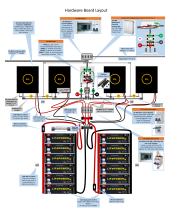

I am helping a couple of friends figure out how to put their systems together. Both of these will be inspected by the local B.D.. One is putting together 6kW of panels and the other 27kW. One will have 2*LVX6548 inverter/charge controller and the other will be a 4 stack of the same.

So my question today is: How are people combining the AC in and out? My system is older and I have Magnum inverters and use the Magnum panel box. Slick and clean, if expensive. I really like mine, it has all of the connections you need, along with AC in and out breakers, breaker for the generator input and so on. Is there a generic, brand agnostic box to use? Or how are folks combining multiple inverters? I guess it would be possible to use the Magnum or Schneider panels boxes, it just won't have the slick mount for the inverter itself.

Thanks!

I am helping a couple of friends figure out how to put their systems together. Both of these will be inspected by the local B.D.. One is putting together 6kW of panels and the other 27kW. One will have 2*LVX6548 inverter/charge controller and the other will be a 4 stack of the same.

So my question today is: How are people combining the AC in and out? My system is older and I have Magnum inverters and use the Magnum panel box. Slick and clean, if expensive. I really like mine, it has all of the connections you need, along with AC in and out breakers, breaker for the generator input and so on. Is there a generic, brand agnostic box to use? Or how are folks combining multiple inverters? I guess it would be possible to use the Magnum or Schneider panels boxes, it just won't have the slick mount for the inverter itself.

Thanks!