Well, the gal doesDo you guys think these settings can provide charger hysteresis?

Me too.I think that's what it looks like to me.

Well, the gal doesDo you guys think these settings can provide charger hysteresis?

Me too.I think that's what it looks like to me.

Never heard of it, thanks for the info maybe I'll consider it for the next packs after I delete my flexible cutting board stock ?.Thanks to the zealous rigor of some this forum's members, I guess I am now obligated to seek an amount of FR-4 Garolite separator material that Amazon is now asking me if I'd like to pay for it in installments...

Thanks to the zealous rigor of some this forum's members, I guess I am now obligated to seek an amount of FR-4 Garolite separator material that Amazon is now asking me if I'd like to pay for it in installments...

They did and I see now that's no insignificant accessory. They're probably getting a much better deal on that FR-4 in China.Did your LF304s come with two separators in each box? I’m not sure exactly what material it is, but I assumed it would be used between cells.

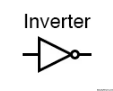

Looks like an Op amp.love your symbol for inverter

Looks like an Op amp.

Works for me..

Seagal puts her nerd hat on...

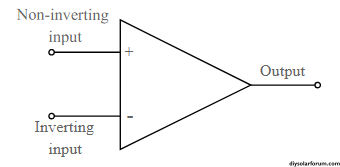

An op-amp is a linear circuit that has two inputs which amplifies the difference between the +ve and -ve inputs. The symbol is like this..

View attachment 178285

An inverter (of the component type) is a digital circuit that has one input and one output. The output is the inverse digital signal to the output. So an input of 1 (typically +3.3V or +5V) would result in an output of 0 (0V). And vice versa. The symbol is like

Yea. Looks like NOT gate..Gone a bit off topic, but... Visio...

View attachment 178314

Texas Instruments 7404...

View attachment 178316

Hmmm. Might have to request a different version.Gone a bit off topic, but... Visio...

View attachment 178314

Texas Instruments 7404...

View attachment 178316

Is there any room at the top to add some sort of padding for additional protection?One of the most catastrophic hazards I have in mind is an earthquake that could tip the toolbox over, with the cell terminals landing into the metal case. I'm gonna put kapton tape over them but that's not really a guarantee of protection.

I would run additional support, maybe strut, on the backside that joins the 2 boxes. Fasten the bottom to the concrete and the additional support to the wall.For a single toolbox, the chances that an earthquake could even tip them over is pretty unlikely I think, with the 2x8 footprint of the compressed cell bank. But, I have an expansion plan that involves another toolbox of 16 cells on top of this one, which could easily tip if not secured.

My two securing options are either to bolt the box to the concrete floor, or bolt it to the wood stud wall. Wood stud wall is a lot easier, but it puts the case up in direct wood contact which is a fire concern. Cells venting and catching on fire is I think one of the most unlikely scenarios.

Considering two boxes on top of each other, I'm not actually sure which is stronger. If the first one is bolted to the ground and the second one is bolted to the first one, that's a lot of lateral force on the bottom one's concrete anchors with 200lbs 2ft off the ground moving back and forth.

Yea. Looks like NOT gate..

I usually just draw a box. ?